|

|||

|

|

|||

|

Page Title:

CHAPTER 8. ASSEMBLY OF TRANSMISSION FROM SUBASSEMBLIES |

|

||

| ||||||||||

|

|

TM 9-2520-249-34&P

CHAPTER 8

ASSEMBLY OF TRANSMISSION FROM SUBASSEMBLIES

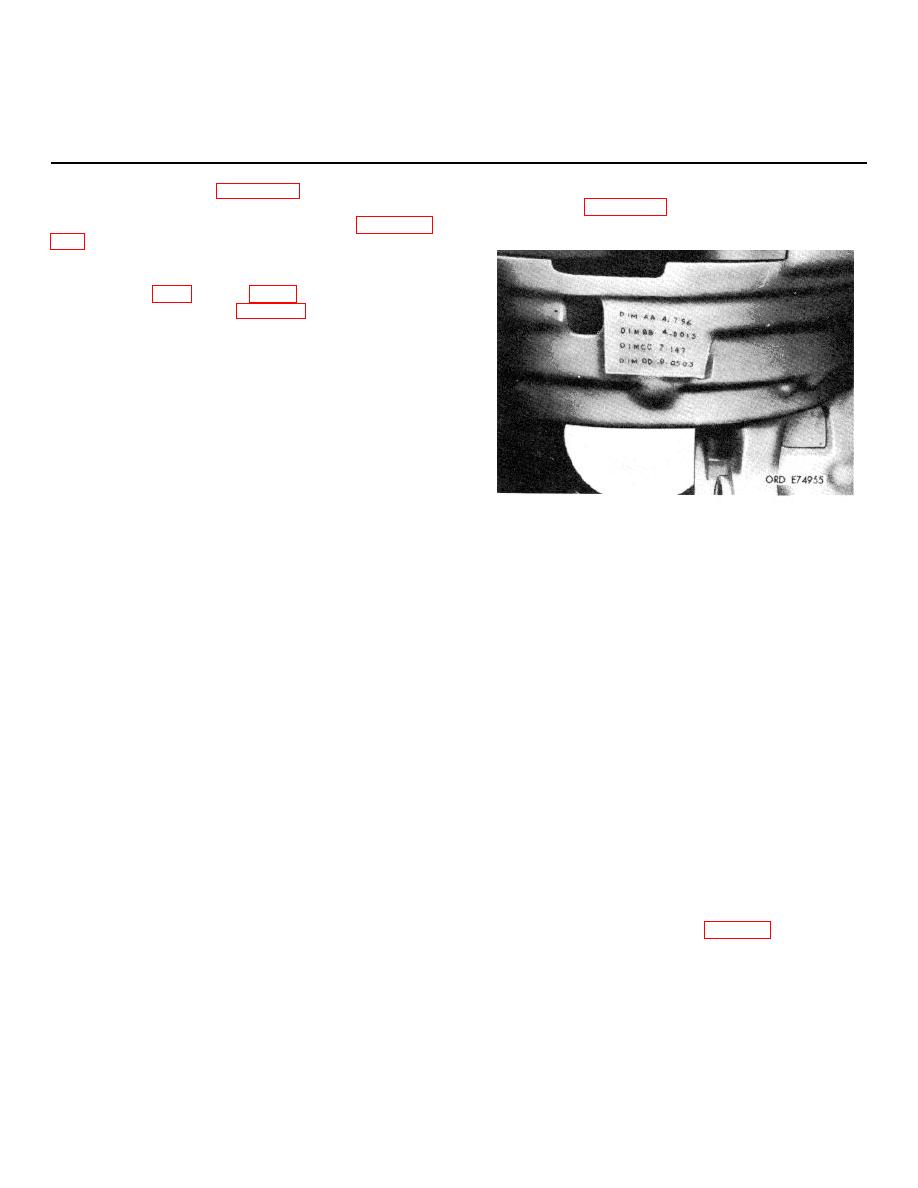

called "case" dimensions and are specific for each bevel

8-1.

Arrangement of Chapter 8

gear housing. Figure 8-1 shows the location of case

Assembly procedures for the transmission, arranged in

dimensions.

consecutive, pictorial steps, commence with paragraph

the bevel gears are given in the paragraphs immediately

following. Also, references will be made to exploded

to special tool information (chapter 3), as needed.

8-2.

Shimming and Adjusting Bevel Gears

a. Matched Components.

(1) The bevel drive gear, bev l driven

e

gear, and brake coolant pump bevel drive gear are

matched components in a set and must be properly

positioned and adjusted in relation to each other.

Correct backlash, gear tooth contact and bearing

preload must be established during assembly of the

transmission.

(2) Steel shims of various thickness are

used to position the gears and to produce the proper

Figure 8-1. Case dimensions stamped on bevel gear

preload on the tapered roller bearings on which the

housing.

bevel drive gears and cross shaft are mounted.

b. Shimming Outlined. The instructions which

(2) Other dimensions must be accurately

follow outline the procedures required to do the

measured during adjustment procedures. The mounting

complete job of shimming and gear setting. However,

dimensions (MD) etched on the gears, the case

when a transmission is rebuilt, the extent of the job will

dimensions and the dimensions measured during

be determined by the extent of factors which prevent

adjustment are all used in the formulas for determining

using the original shim packs.

the nominal (approximate) shim pack thicknesses.

c. When to Use New Shims. Some of the

e. Shimming Illustrated.

Line drawings

factors which prevent using the original shims are:

illustrate each major step in determining the nominal

(1) Evidence of incorrect setting of gears

shim pack thicknesses.

in previous assembly. This can be recognized by

f.

Record Prior to Adjustments. Record all

abnormal gear contact wear pattern.

backlash, mounting distance and case dimensions

(2) Loss or mixing of shims removed

before beginning the gear-setting procedures.

during disassembly. Always tie each shim pack together

g. Final Adjustments. After the nominal shim

at the time of removal and identify its location. As

packs are determined, the gear setting and bearing

added precaution, record the thickness of each shim

preload must be further adjusted to obtain the proper

pack and its location.

backlash, gear tooth pattern and drag torque

(3) Replacement of any components

characteristics.

which, because of manufacturing tolerances, will not be

dimensionally identical to original components.

8-3.

Determining Nominal Shim Between Bevel

d. Stamped and Etched Dimensions.

Drive Gear Support and Carrier

(1) Each gear set is matched during

manufacture and etched with a gear set number,

approximately zero end play of the bevel drive gear

prescribed backlash (BL), and mounting dimension

within its carrier and support.

(MD). Lettered dimensions AA, BB, CC and DD are

tamped on a web in the bevel gear housing. These are

8-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |