|

|||

|

|

|||

|

Page Title:

Section XXVII. INPUT OIL PUMP ASSEMBLY-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34&P

a. If plug (85) was removed from valve body

spring (81) from valve body (84).

(84), install a new replacement part.

e. Do not remove plug (85) unless

b. Install cooler bypass valve spring (81) onto

replacement of parts is necessary.

If necessary,

seat (79). Install the spring and seat, spring end first,

remove the plug.

into the valve body.

c. Install bypass valve ball (77).

d. Install bypass valve seat (75), chamfered

7-154. Cleaning

inside diameter side first, into valve body (84).

Refer to paragraph 5-2 for cleaning recommendations.

e. Install retaining ring (74).

f.

Install lubrication regulator valve seat (83),

7-155. Inspection and Repair

flat side first, into valve body (84).

Refer to paragraph 5-3 for general inspection and repair

g. Install retaining ring (82).

recommendations.

h. Install lubrication regulator valve (80), large

end first, and spring (78).

7-156. Repair Standards

i.

Install valve guide (76), small diameter

first, onto valve (80) and against valve spring (78) in

repair standards.

valve body (84). Secure guide (76) with retaining ring

(74). Refer to figure 7-54.

7-157. Assembly (FO 10)

Table 7-22. Repair Standards (Lubrication Regulator Valve

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

10

78a,

Free length of spring.............................

2.16

*

81a

10

78a,

Length under load ................................

1.16 at 10.50 to

1.16 at 10.25 lb

81a

11.50 lb

*Replace when worn beyond new dimensions.

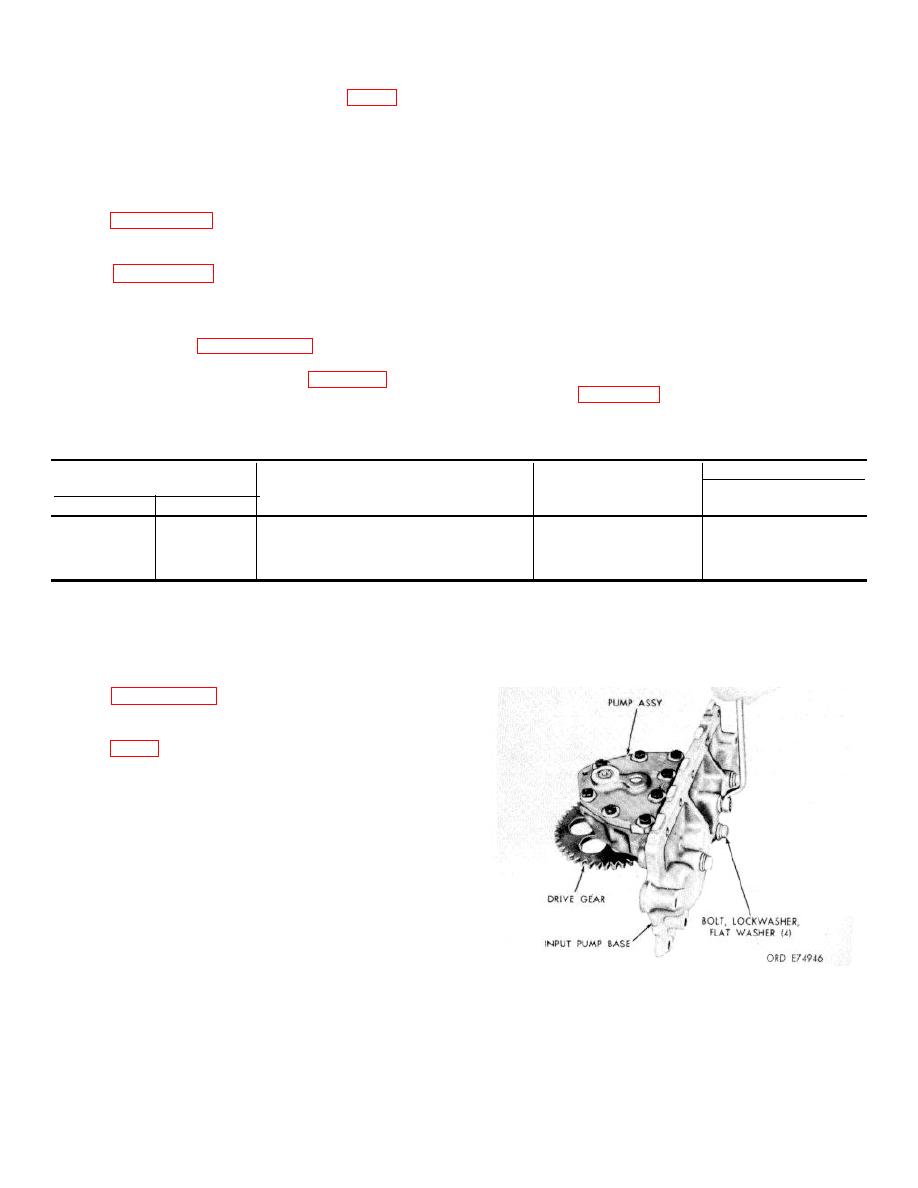

Section XXVII. INPUT OIL PUMP ASSEMBLY-REPAIR

7 -158. Description

Refer to paragraph 2-2 for description of the input oil

pump components.

7-159. Disassembly

washers, and input pump base with gasket from the

input pump body. Refer to figure 7 55.

Figure 7-55 Removing for installing) input

pump base bolt.)

7-49

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |