|

|||

|

|

|||

|

Page Title:

Section XX. RIGHT AND LEFT OUTPUT HOUSING ASSEMBLY-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

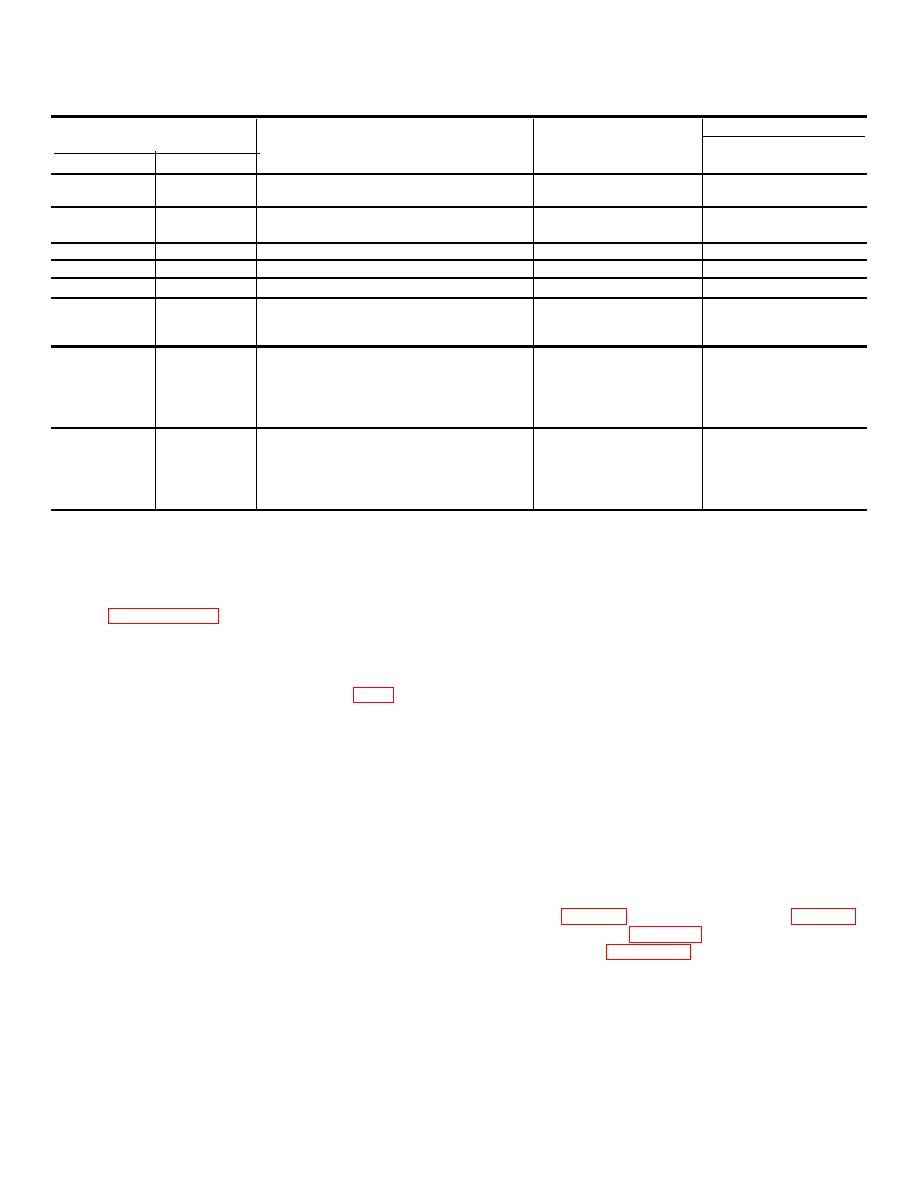

Table 7-16. Repair Standards (Right, Left Output Clutch Assemblies)-Continued

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

8

99b

Inside diameter of piston housing at seal-

7.875 to 7.881

7.885

rings................................ .....................

8

99a

Inside diameter of housing sleeve at seal-

3.750 to 3.752

3.7540

rings................................ .....................

8

104a

Inside diameter of piston at sealring .....

4.500 to 4.502

4.5040

8

105a

Thickness of disk................................ ..

0.095 to 0.098

8

106a

Thickness of disk................................ ..

0.1 18 to 0.124

0.108

8

109a

Free length of spring.............................

1.9820

*

8

109a

Length under load ................................

1.806 at 10.9 to

1.806 at 10.55 lb

12.33 lb

8

111a

Outside diameter of bearing .................

4.3301 to 4.3307

*

8

113a

Inside diameter at bearing surface of ...

4.3306 to 4.3316

4.3326

housing ................................ ................

8

111a,

Fit of bearing in housing .......................

0.0001T to 0.0015L

113a

8

111b

Inside diameter of bearing ....................

2.773 to 2.7559

*

9

4a

Outside diameter at bearing surface of .

2.7549 to 2.7559

2.7546

carrier ................................ ..................

8,

111b,

Fit of bearing on carrier ........................

0.0006T to 0.0010L

9

4a

*Replace when worn beyond new dimensions.

Section XX. RIGHT AND LEFT OUTPUT HOUSING ASSEMBLY-REPAIR

coolant pressure retaining valve assembly, items (76

7-116. Description

through 79) unless replacement of parts is necessary. If

Refer to paragraph 2-26 for description of the right and

necessary, remove spring guide (79) spring (78), valve

left output housing assemblies.

(77), and valve seat (76).

(6) Do not remove plug (80) unless

7-117. Disassembly

replacement is necessary or to aid in the cleaning of the

output Housing. If necessary, remove the plug.

a.

Right Output Housing Assembly FO-8).

(7) Do not remove roll pin (81) unless

(1) Do not remove plugs (64, 65, and 66)

replacement is necessary. If necessary, remove the pin.

unless replacement is necessary or to aid in the

(8) Flatten tab lockwasher (55) and

cleaning of the output housing. If necessary, remove

remove retaining bolt (54), washer (55) and roller

the plugs.

bearing retaining plate (56). Remove three output

(2) Do not remove dowel pins (67 and 73)

clutch sleeve bolts (57) and three flat washers (58).

unless replacement is necessary. If necessary, remove

(9) Remove

output

clutch

sleeve

the pins.

assembly (88) with two sealrings (91).

Remove

(3) Do not remove insert staking pins (68,

sealrings (91) from sleeve assembly (88).

72, and 75) and screw thread inserts (69, 71, and 74)

(10) Do not remove reduction gear roller

unless replacement is necessary. If necessary, remove

bearings (21 and 36) from housing (63) unless

the pins and inserts.

replacement is necessary. If necessary, use puller

(4) Do not remove three output pump

adapter (3, table 3-1), puller attachment (17, table 3-1),

needle bearings (70) unless replacement is necessary.

and puller kit (18, table 3-1) to remove the roller

If necessary, remove the bearings.

bearings. Refer to figure 7-45.

(5) Do not remove brake and steer

7-37

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |