|

|||

|

|

|||

|

Page Title:

Table 7-16. Repair Standards (Right, Left Output Clutch Assemblies) |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

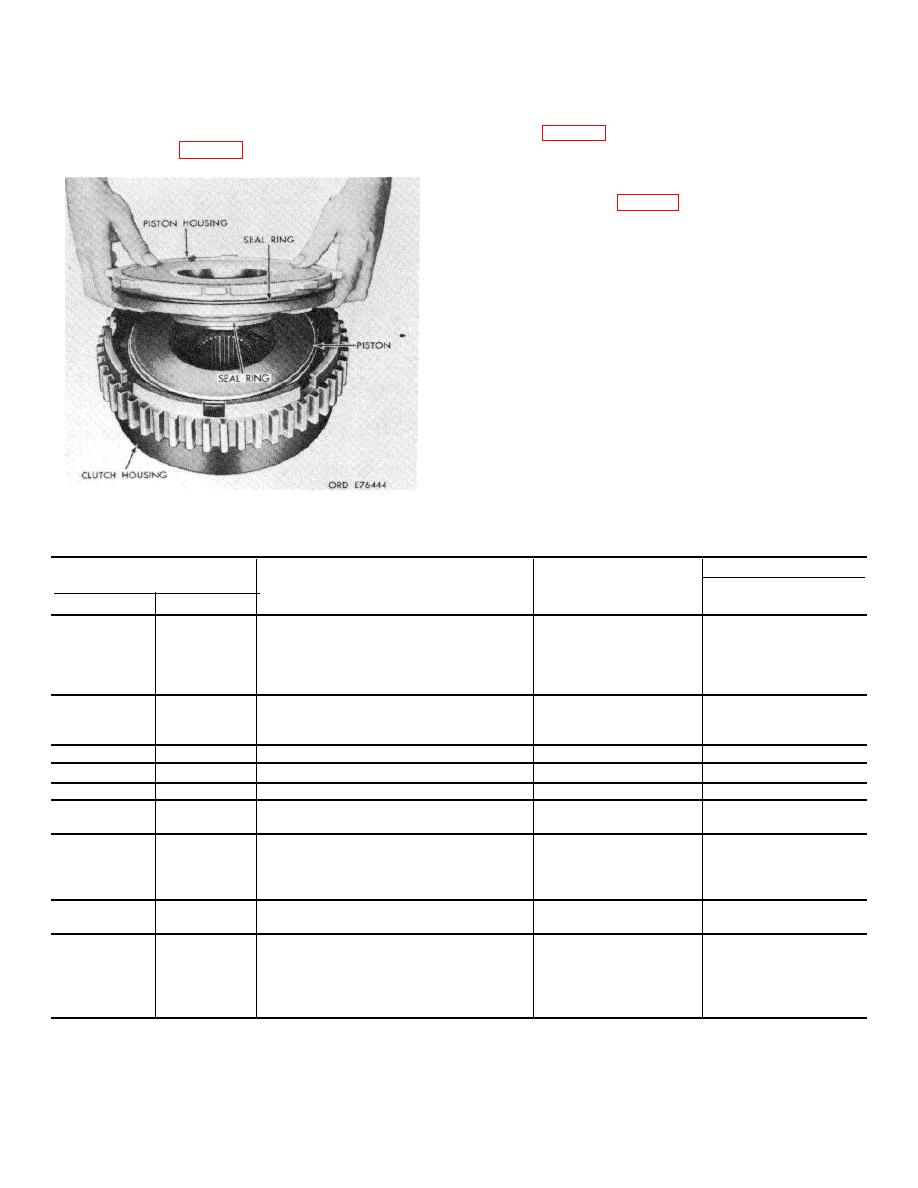

n. Install the hook-type sealring onto the hub of the

o. Aline the tangs on the piston housing with

piston housing. Using a liberal amount of oilsoluble

the slots in the clutch housing and install the piston

grease, install the sealring at the outer circumference of

housing (fig. 7-44).

the piston housing (fig. 7-44).

p. Position the clutch assembly in a press.

Apply sufficient pressure to push the piston housing into

the clutch housing so that the snapring can be installed.

Install the snapring (fig. 7-35).

Figure 7-44. Installing output clutch piston housing

Table 7-16. Repair Standards (Right, Left Output Clutch Assemblies)

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

7

19a

Inside of diameter at hearing surface of

4.3306 to 4.3316

4.3326

housing ................................ ................

7

20b

(Outside diameter of bearing.... ............

4.3301 to 4.3307

*

7

19a,

Fit of hearing in housing. ......................

0.0001T to 0.0015L

20b

7

24a

Free length of spring.............................

1.982

*

7

24a

Length under load...... ..........................

1.806 at 10.9 to

1.806 at 10.55 lb

12.33 lb

7

26a

Thickness of disk................................ ..

0.118 to 0.124

0.108

7

27a

Thickness of disk................................ ..

0.095 to 0.098

*

7

28a

Inside diameter of piston at sealring .....

4.500 to 4.502

4.504

7

33a

Inside diameter of housing sleeve at seal-

3.750 to 3.752

3.754

rings................................ .....................

7

33a

Inside diameter of housing....................

3.8784 to 3.8814

3.8834

7

43a.

Out side diameter at surface of sleeve ..

3.8745 to 3.8755

3.8735

7

33a

Fit of sleeve in housing................. ........

0.0029L to 0.0069L

43a

7

33b

Inside diameter of piston housing at seal-

7.875 to 7.881

7.885

ring ................................ ......................

8

99a

Outside diameter at hushing surface of .

3.8748 to 3.8755

3.8735

sleeve ................................ ..................

8

89a.

Inside diameter of housing....................

3.8784 to 3.8814

3.8834

99a

Fit of sleeve in housing.........................

0.0029L. to 0.0069L

99a

*See footnote at the end of table.

7-36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |