|

|||

|

|

|||

|

Page Title:

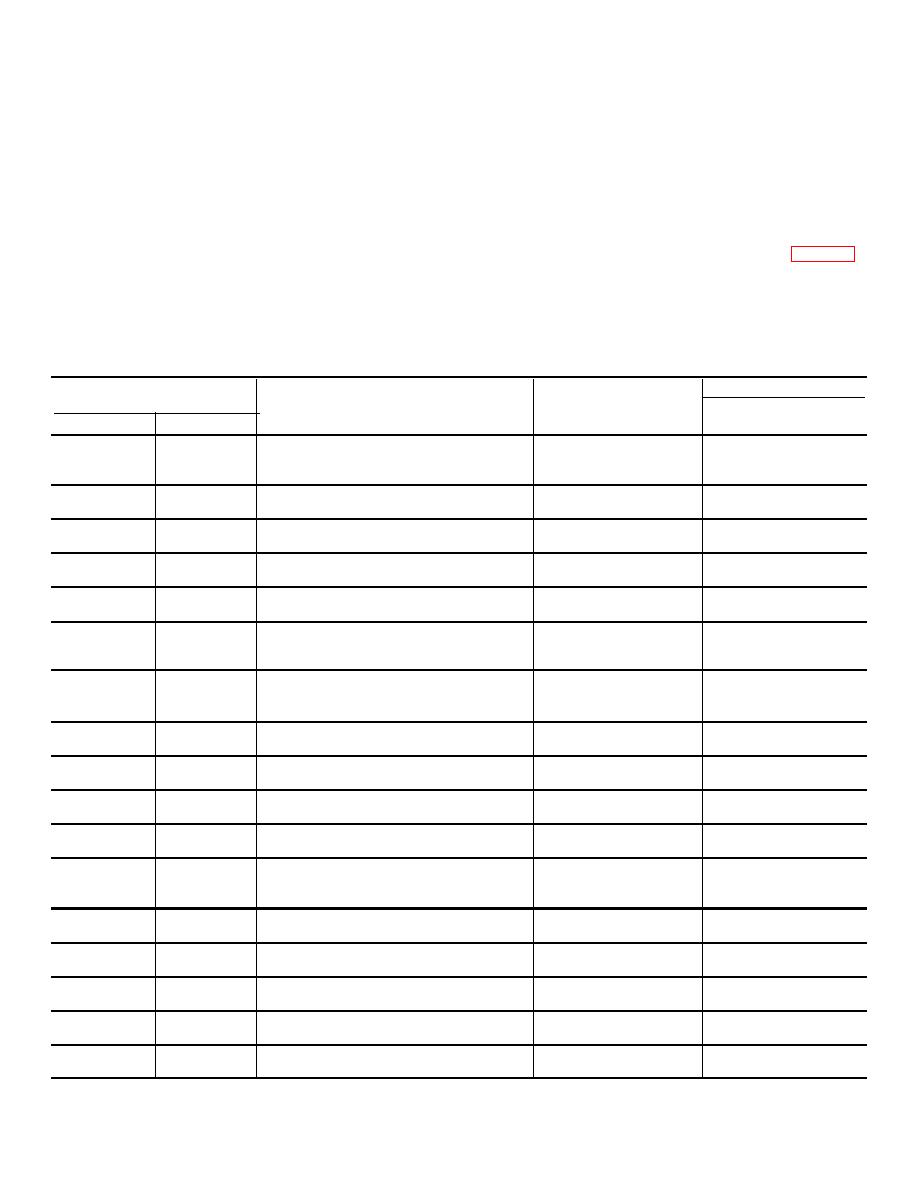

Table 7-15. Repair Standards (Right, Left Brake, Steer Clutch) |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

engage pins (6).

inside diameter downward, over oil baffle plate (7) and

j.

Install 12 springs (13) onto pins (15). Push

clutch disks (12 and 14). Rotate plate assembly (5) until

the through-holes in plate (7) aline with the 12 pins (15).

them through the holes in plate (7) and against disk (16).

h. Lower plate assembly (5), and guide spring

k. Install apply disk (2). flat side upward

guide pins (15) through the holes in plate (7). At the

(counterbores of smaller holes downward), onto the

same time, engage pins (6) with the cutouts in disks (12

assembly. Aline the smaller holes to engage all 12 pins

and 16). Also, two pins (8) in plate (7) must engage the

(15).

two slots in oil baffle plate (11). The ends of pins (6) in

l.

Using a press or C clamps, depress the

plate (7) should now rest on the flat surface on which the

brake apply disk until the pins project through the

entire assembly is sitting.

smaller holes in the disk. Install 12 snaprings (fig. 7-34).

i.

Install six external-tanged disks (4) and six

Release the pressure and remove the assembly from

internal-splined disks (3) alternately upon plate

the press.

assembly (5). Begin with an external-tanged disk (14).

The smaller cutouts in the tangs of disks (4) must

Table 7-15. Repair Standards (Right, Left Brake, Steer Clutch)

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

7

2a

Thickness of disk................................ ..

0.2420 to 0.2540

0.2410

7

3a

Thickness of disk................................ ..

0.1580 to 0.1630

0.1480

7

4a

Thickness of disk................................ ..

0.1166 to 0.1226

7

1a

Thickness of baffle plate.......................

0.2400 to 0.2600

0.2200

7

12a

Thickness of disk................................ ..

0.1166 to 0.1226

*

7

13a

Free length of spring.............................

5.238

7

13a

Length under load ................................

3.99 at 27.13 to

3.99 at 25.63 lb

33.17 lb

7

14a

Thickness of disk................................ ..

0.1580 to 0.1630

0.1480

7

16a

Thickness of disk................................ ..

0.2420 to 0.2540

0.2410

8

113a

Thickness of disk................................ ..

0.242 to 0.254

0.241

8

117a

Thickness of disk................................ ..

0.5180 to 0.1630

0.1430

8

118a

Free length of spring.............................

5.238

*

8

118a

Length under load ................................

3.99 at 27.13 to

3.99 at 25.63 lb

33.17 lb

8

1119a

Thickness of disk................................ ..

0.1166 to 0.1226

8

120a

Thickness of baffle plate.......................

0.2400 to 0.2600

0.2200

8

127a

Thickness of disk................................ ..

0.1166 t o0.1226

*

8

128a

Thickness of disk................................ ..

0.1580 to 0.1630

0.1480

8

129a

Thickness of disk................................. .

0.242 to 0.254

0.241

*Replace when worn beyond new dimensions.

7-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |