|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-249-34&P

clutch housing (2).

7-34. Inspection and Repair

b. Remove high-range clutch back plate (11).

Refer to paragraph 5-3 for inspection and repair

c. Remove five internal-splined (10) and five

recommendations.

external-tanged (9) high-range clutch disks.

7-35. Repair Standards

spring retainer (14, (FO-4), compress the spring retainer

repair standards.

and remove retaining ring (15). Refer to figure 7-6.

a. If balls (3) were removed from housing (2),

install new balls. Stake metal in three places at the end

of the hole, to retain the ball, but not to affect its

movement in the hole.

b. Install sealring (8) onto the hub of housing

(2).

c. Install eight high-range clutch anchor pins

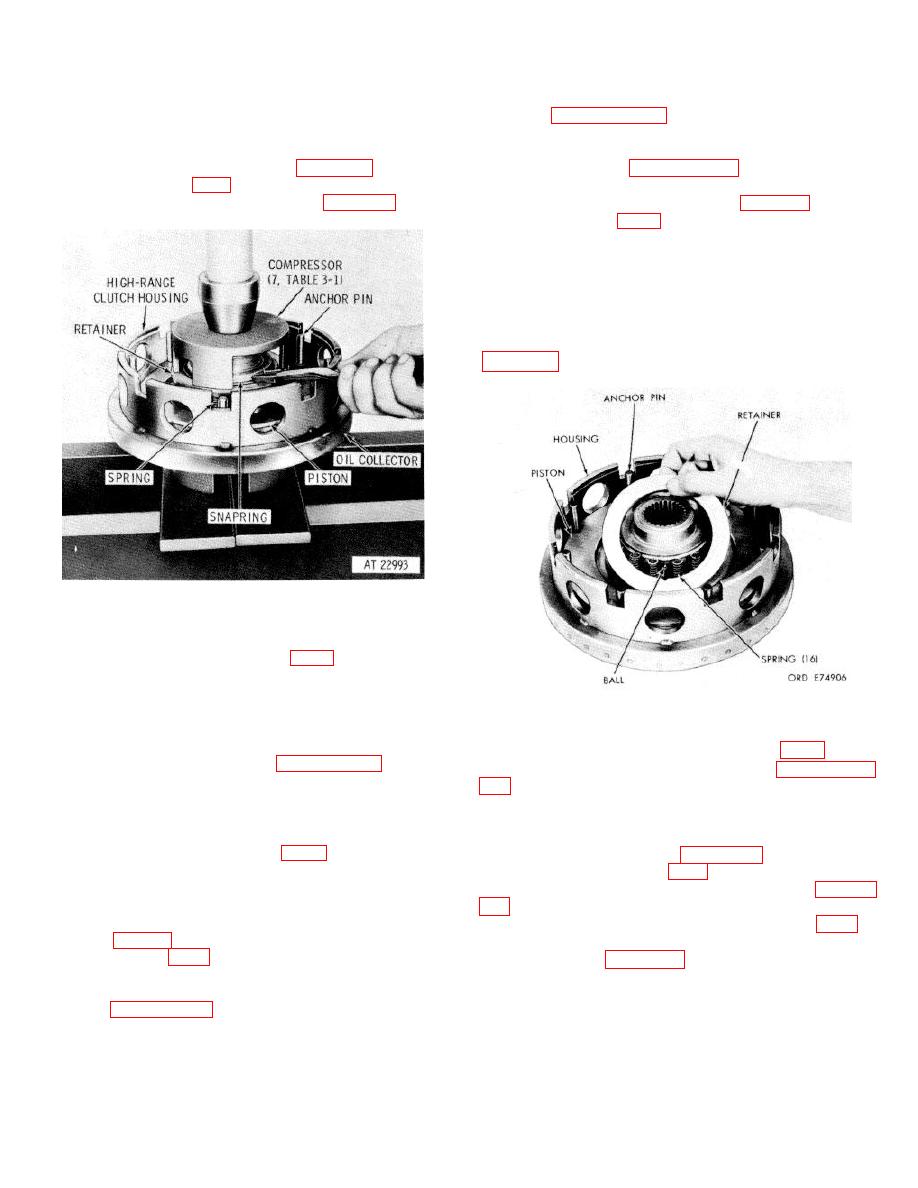

Figure 7-6. Removing (or installing) high-range clutch

piston return spring retainer retaining ring.

springs (12).

f.

Remove spring retainer locating ball (13).

Figure 7-7. Installing high-range clutch piston return

g. Remove eight anchor pins (4).

spring retainer.

h. Remove high-range clutch piston (7).

i.

Remove sealring (5) and expander spring

(6) from piston (7), as outlined in paragraph 7-51.

sealring (5) onto piston (7), as outlined in paragraph 7-

WARNING

55, following.

Do not dispose of Teflon sealrings by

e. Lubricate sealring bores and sealrings with

burning. Toxic gases are produced when

the same oil as used in the power train and carefully

Teflon is burned.

install piston (7) with expander spring (6) and sealring

i.

Remove sealring (8, FO-4) from hub of

(5) into housing (2). Refer to figure 7-7.

housing (2).

f.

Install ball (13, FO-4) into the recess of the

k. Do not remove two balls (3) from housing

housing hub, retaining it with oil-soluble grease (fig. 7-

(2) except for replacement.

l.

Do not remove the oil collector from the

housing (fig. 7-6). If the ring is damaged, the collector

Indexing the retainer (14) with ball (13), install the spring

and housing (2, FO-4) will have to be replaced as an

retainer. Refer to figure 7-7.

assembly.

7-33. Cleaning

Refer to paragraph 5-2 for cleaning recommendations.

7-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |