|

|||

|

|

|||

|

Page Title:

Section VI. HIGH-RANGE CLUTCH ASSEMBLY-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34&P

output shaft (39) Use oil-soluble grease to retain them.

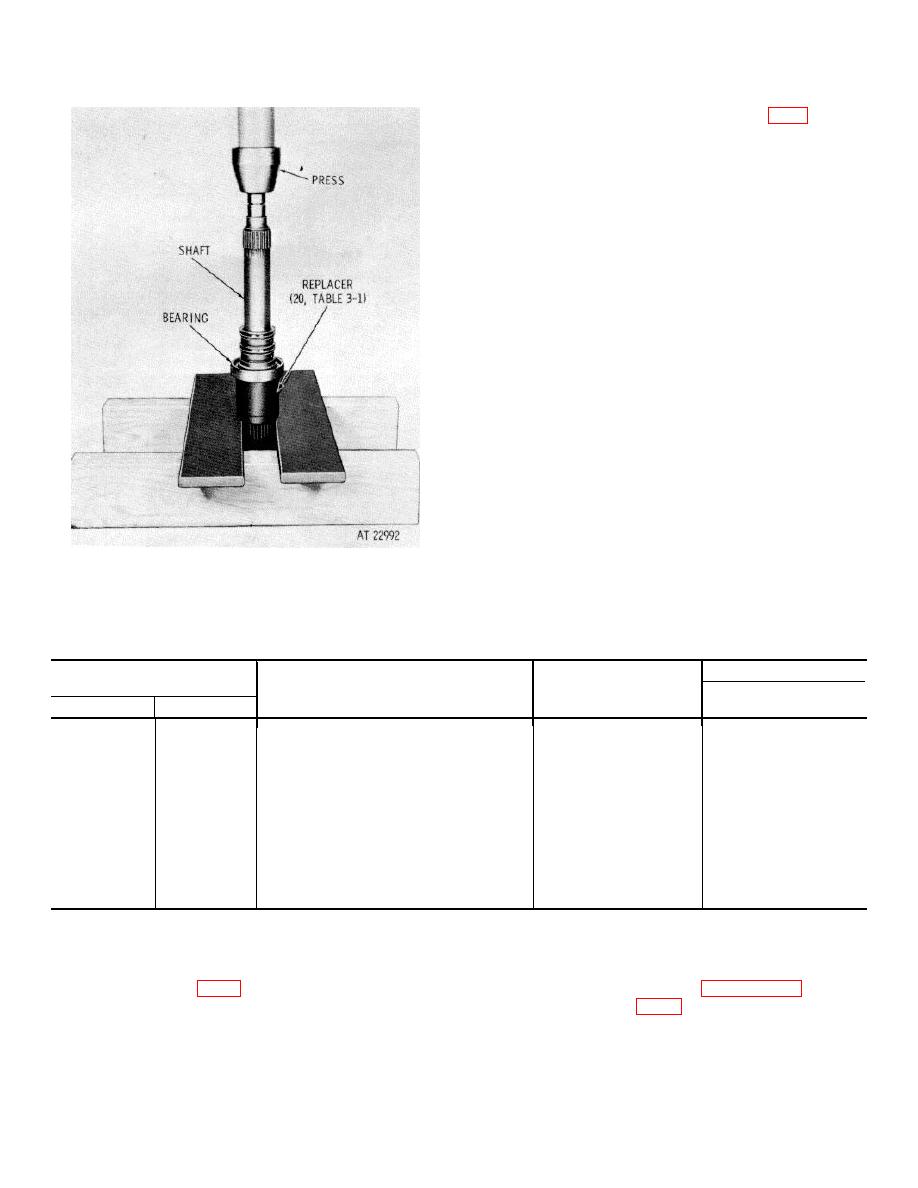

Figure 7-5. Installing bearing onto torque

converter output shaft.

Table 7-4. Repair Standards (Converter Output Shaft)

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

3

36a

Outside diameter of bearing...................

2.9523 to 2.9528

*

3

45b

Inside diameter at bearing surface of sleeve 2.9527 to 2.9537

2.9547

3

36a

Fit of bearing in sleeve........................ .

0.0010T to 0.0014L

45b

3

36b

Inside diameter of bearing.....................

1.7712 to 1.7717

3

39b

Diameter at bearing surface of shaft .....

1.7714 to 1.7724

1.7709

3

36b,

Fit of bearing on shaft ..........................

0.0012T to 0.0003L

39b

*Replace when worn beyond new dimensions.

Section VI. HIGH-RANGE CLUTCH ASSEMBLY-REPAIR

carrier (32), small end. Refer to paragraph 2-5.

The high-range clutch has five external-tanged clutch

disks (9) which engage pins (4), and five internal-splined

a. Remove retaining ring (16) from high-range

disks (10) that spline onto intermediate range planetary

7-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |