|

|||

|

|

|||

|

Page Title:

Input Shaft Disassembly and Assembly. |

|

||

| ||||||||||

|

|

TM 9-2520-246-34

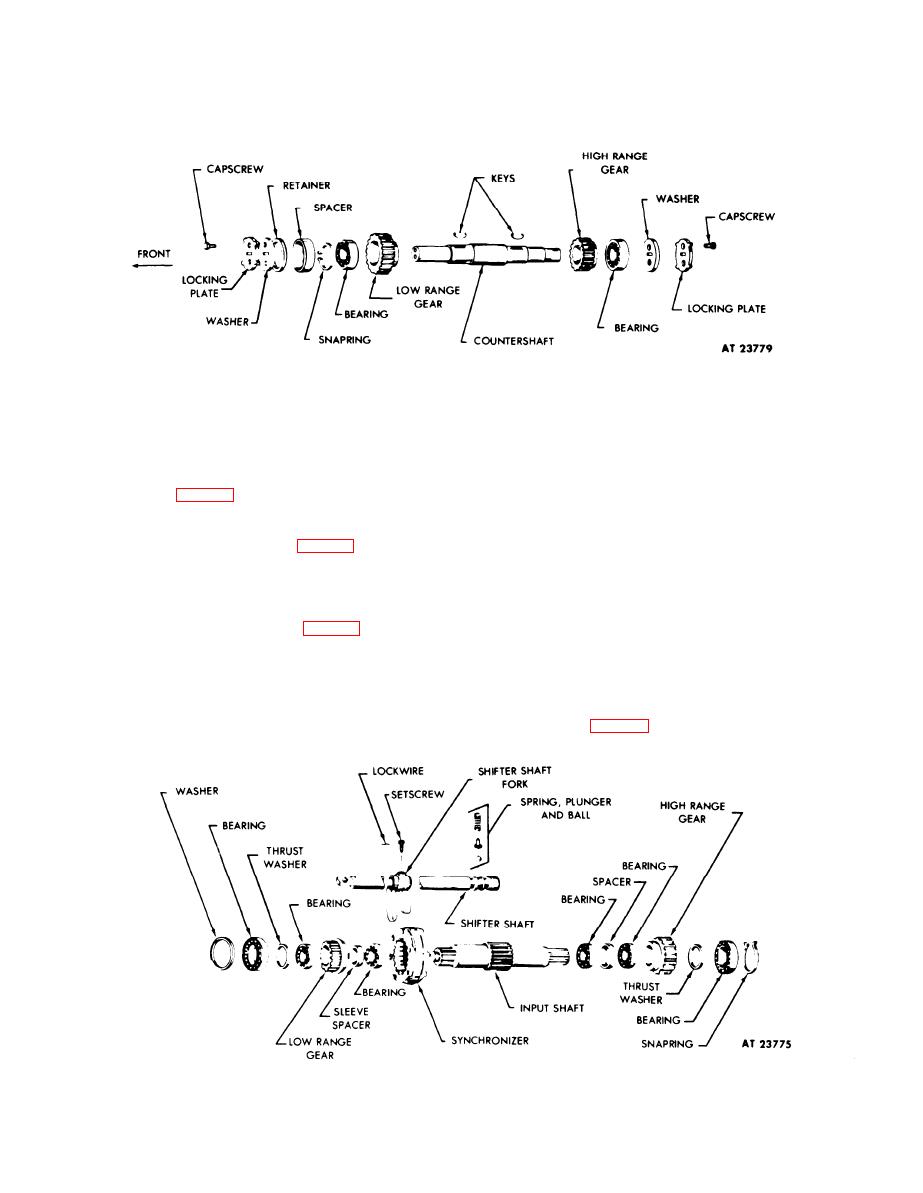

Figure 4-15. Countershaft Disassembly -- Exploded View.

(1) Using a suitable tool, bend the front and rear

NOTE

locking plate ears away from capscrews and remove

capscrews, locking plates, washers, and spacer (front

Visually inspect synchronizer assembly for

broken, nicked, or worn gear teeth. If any

only). (See fig. 4-15.)

of these conditions prevail, the

synchronizer must be replaced. For

(2) Place countershaft in a press with the

replacement, use synchronizer part number

countershaft high range gear (fig. 4-15) and rear

7346755.

bearing up. Place support bars beneath the high range

gear and rear bearing. Remove woodruff key.

NOTE

(3) Place the countershaft assembly in an arbor

press with the low range gear (fig. 4-15) and front

bearing up. Place support bars beneath the low range

gears onto the input shaft, coat all

installation surfaces with white lead

gear. Press shaft from countershaft low range gear

pigment, Fed Spec TT-W-261C.

and front bearing. Snapring and retainer is removed

with transfer case cover. Remove woodruff key.

(1) Remove shifter fork from synchronizer

assembly. (See fig. 4-16.)

c. Input Shaft Disassembly and Assembly.

,

Figure 4-16. Input Shaft Disassembly -- Exploded View.

4-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |