|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-246-34

shaft plug (fig. 4-11). Remove valve assembly (fig. 4-

n. Rear Output Shaft Rear Bearing Retainer.

12) from PTO flange.

NOTE

NOTE

During assembly, tighten the rear output

shaft rear bearing retainer capscrews to 60-

On assembly, install the valve with spring

77 lb-ft torque. Use shims to obtain 0.002-

toward inside of case.

to 0.005-inch end play. The shims are

provided as a set. The part number for the

4-6. Disassembly of Subassemblies.

set is 7521437. The part numbers and shim

sizes are:

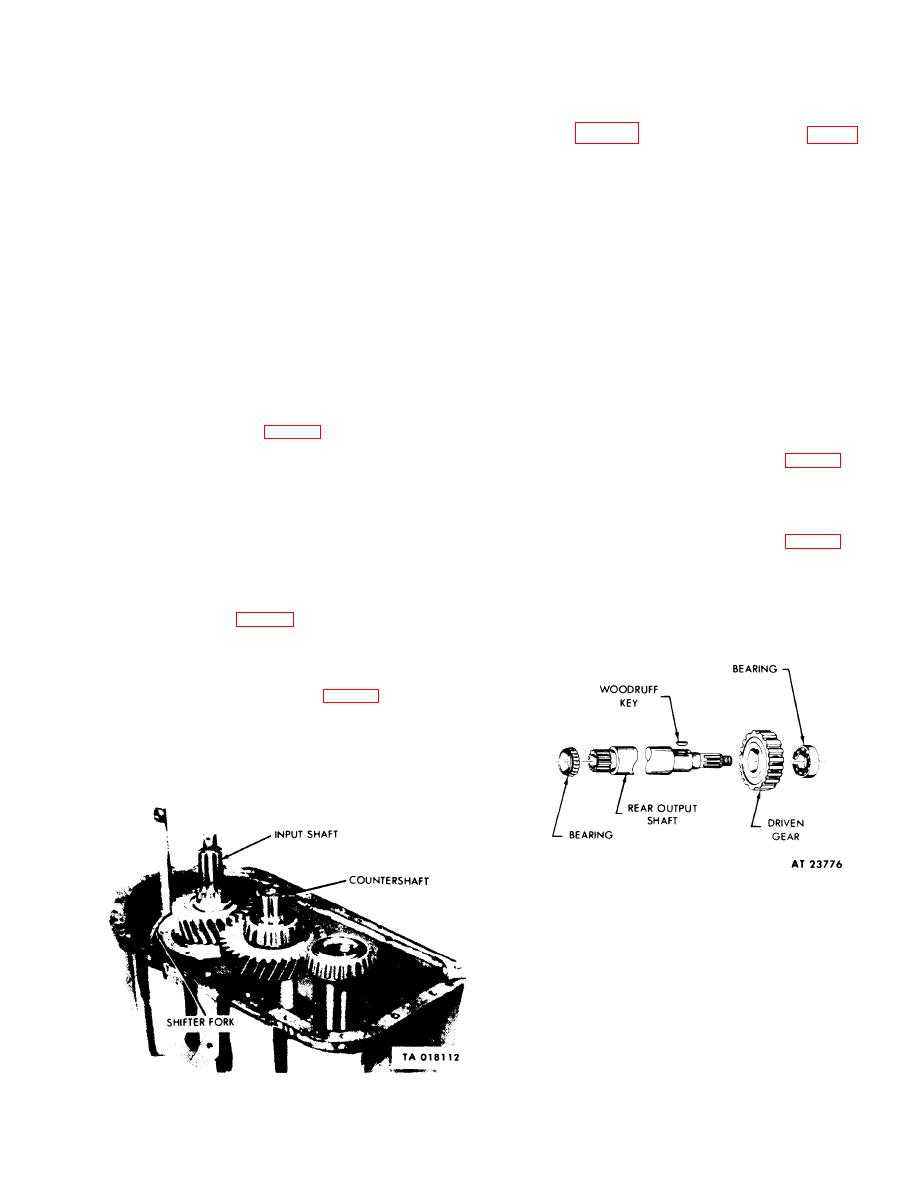

a. Rear Output Shaft Disassembly and Assembly.

Thickness

Ordnance No.

NOTE

.003 .001

7521277

Before pressing the gear and bearings on

.005 .001

7521278

rear output shaft, coat shaft with white

.010 .001

7521279

lead pigment, Fed Spec TT-W-261C. When

assembling the rear output shaft assembly,

Remove the six capscrews and lockwashers

install the parts separately, so as not to

securing the rear output shaft rear bearing retainer to

damage front and rear bearings.

the transfer case. (See fig. 4-12.) Remove bearing

retainer and shims from the rear output shaft bearing

(1) Place rear output shaft assembly (fig. 4-14) in

retainer.

an arbor press with front tapered roller bearing cone

o. Input Shaft Rear Bearing Cover.

up. Place support bars beneath the cone. Press shaft

from cone.

NOTE

(2) Place rear output shaft assembly (fig. 4-14) in

During assembly, install a new gasket.

an arbor press with the rear output shaft driven gear

Tighten capscrews to 60-77 lb-ft torque.

up. Place support bars beneath the rear output shaft

Remove the six capscrews and lockwashers

driven gear and press shaft free of the gear. Removal

securing the input shaft rear bearing cover to the

of the rear output shaft driven gear in this manner

transfer case. (See fig. 4-12.) Remove rear bearing

will also push the rear output shaft rear bearing from

cover and gasket; discard the gasket.

the shaft. Remove the woodruff key from the shaft.

p. Shifter Fork, Input Shaft Assembly and

Countershaft Assembly. Using a soft pin and hammer,

drive the input shaft loose. (See fig. 4-13.) Then lift

the input shaft assembly, synchronizer assembly, fork

assembly, and countershaft assembly from the transfer

case.

q. Transfer Case Shifter Shaft Plug and Valve

Assembly. Using a suitable tool, remove the shifter

Figure 4-14. Rear Output Shaft Disassembly

-- Exploded View.

b. Countershaft Disassembly and Assembly.

NOTE

countershaft, coat shaft with white lead

pigment, Fed Spec TT-W-261C. When

assembling the countershaft assembly,

install parts separately so as not to damage

front and rear bearings. Discard old

capscrew locking plates and replace with

Figure 4-13. Shifter Fork, Input Shaft, and Countershaft.

new.

4-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |