|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-238-34

REPAIR DIFFERENTIAL RIGHT ANGLE GEARBOX -- Continued

0028 00

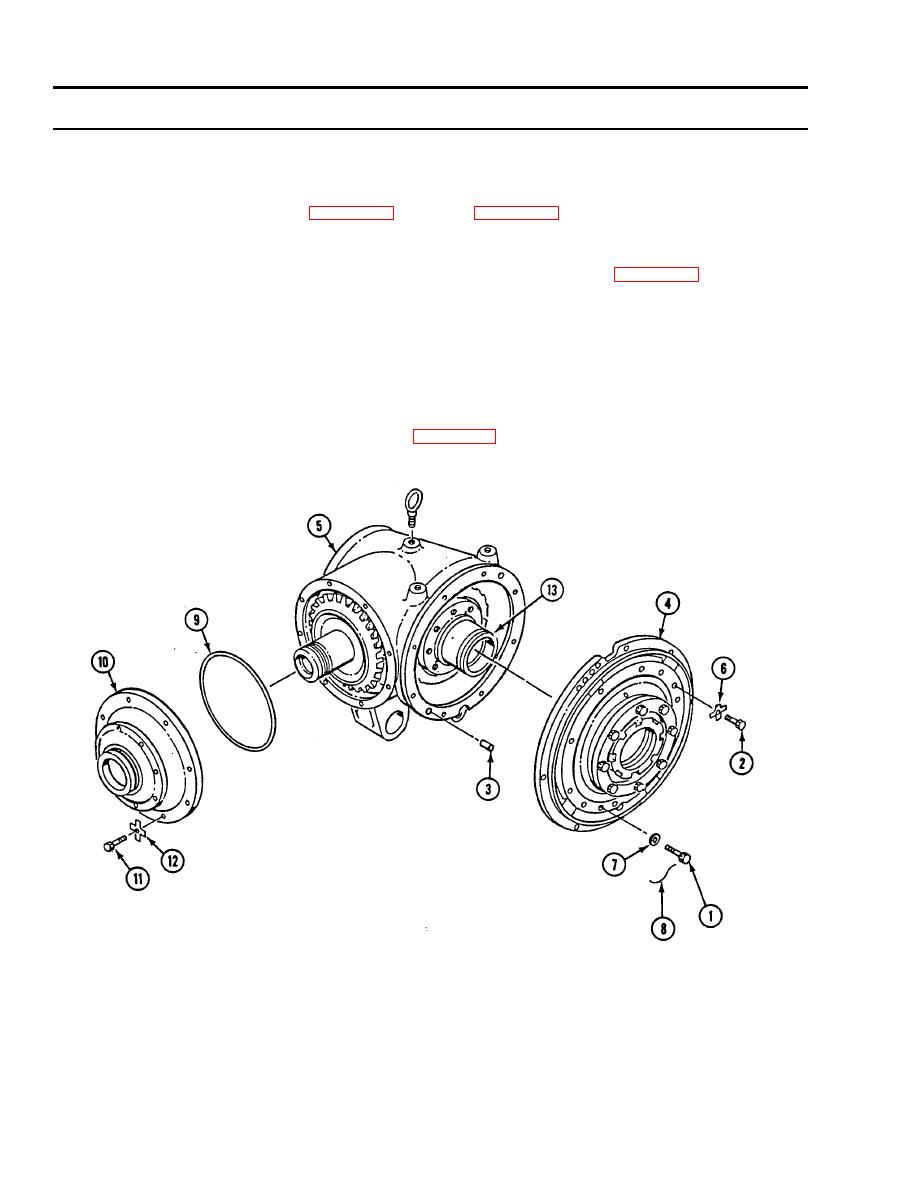

51. Remove four cap screws (1).

52. Clean 10 cap screw threads of cap screws(1), cap screws(2), and 2 alignment pins (3).

53. Apply a thin film of sealing compound (WP 0035 00, Item 12) or (WP 0035 00, Item 13) to 10 cap screw threads of cap

screws (1), cap screws(2) and 2 dowel holes marked G on surfaces in contact with adapter plate (4).

54. Secure output assembly on gearbox housing (5) with two new key washers (6), cap screws (2), eight washers (7), and cap

screws (1). Tighten screws (1) to 300-360 lb-in (34-41 Nm) torque. Use torque wrench (WP 0033 00, Item 41). Bend

tabs on two key washers.

55. Secure eight cap screws (1) in pairs with new lockwire (8) (four places with 13 inches (33 cm) minimum length of wire

required for each place).

56. Lubricate new preformed packing (9) with grease or petrolatum. Install packing on bearing housing (10).

57. Clean threads of eight cap screws (11). Apply light coat of antiseize compound to threads at installation.

58. Secure input assembly on gearbox housing (5) with eight new key washers (12) and cap screws (11). Tighten screws to

252-300 lb-in (28-34 Nm) torque. Use torque wrench (WP 0033 00, Item 41). Bend tabs on key washers.

59. Coat interior splines of hub (13) with engine oil.

0028 00-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |