|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-238-34

REPAIR DIFFERENTIAL RIGHT ANGLE GEARBOX -- Continued

0028 00

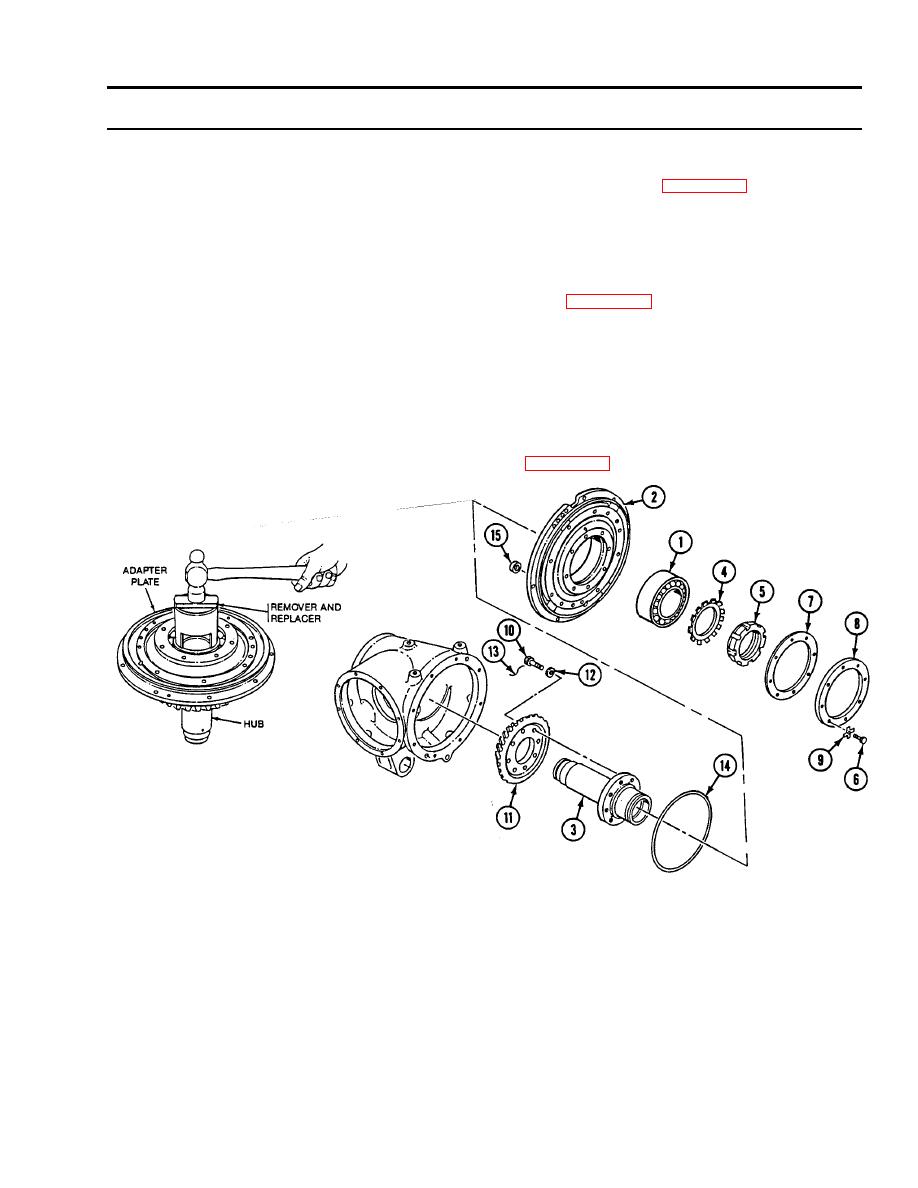

28. Install ball bearing (1) in adapter plate (2). Use a soft plastic hammer.

29. Place bearing (1) with plate (2) to hub (3) and install bearing. Use remover and replacer (WP 0033 00, Item 23) and

hammer.

30. Secure hub (3) to bearing (1) with new key washer (4) and round nut (5). Bend tangs on key washer.

31. Lubricate four cap screws (6) with engine oil.

32. Without shim (7) installed, place bearing retainer (8) on plate (2). Secure with four cap screws (6) spaced 90 degrees

apart. Tighten screws to 14-16 lb-in (1 N.m) torque. Use torque wrench (WP 0033 00, Item 39).

33. Measure and record gap between retainer (8) and plate (2) at four equal places around retainer and determine the average

of the readings and subtract .002-.003 inch (.005-.008 cm) to obtain required deflection in retainer (8). Peel shim (7) to

this thickness or to the next laminate thinner.

34. Remove four cap screws (6) and retainer (8) from plate (2).

35. Clean threads of eight cap screws (6). Apply light coat of antiseize compound to threads at installation.

36. Place peeled shim (7) and retainer (8) on plate (2). Secure with eight new key washers (9) and cap screws (6). Tighten

screws to 252-300 lb-in (28-34 Nm) torque. Use torque wrench (WP 0033 00, Item 41). Bend tabs on key washers.

0028 00-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |