|

|||

|

|

|||

|

Page Title:

Determine thickness of new laminated shim |

|

||

| ||||||||||

|

|

TM 9-2520-238-34

REPAIR TRANSFER GEARCASES A, B, AND C -- Continued

0017 00

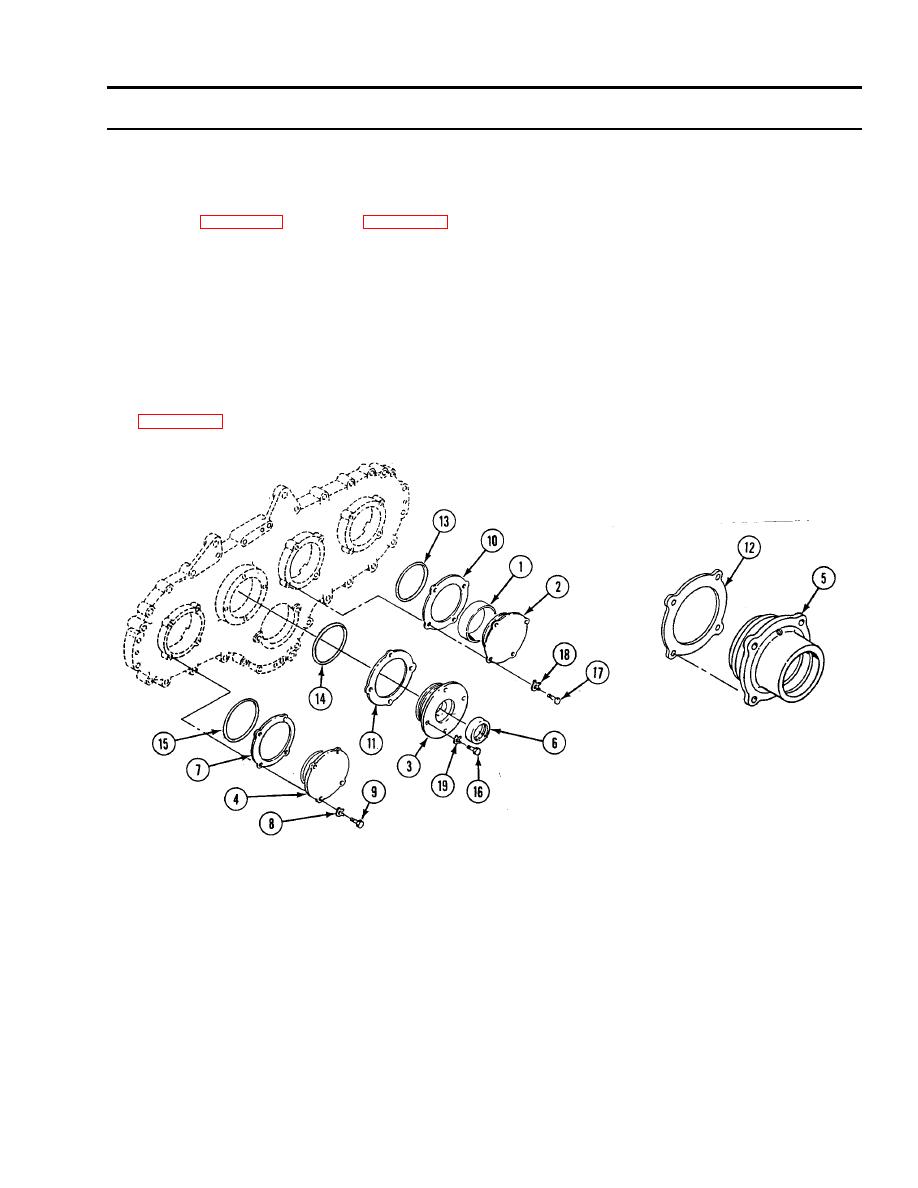

22. If removed, install bearing cups (1) in retaining plate (2), or retaining plate (3), or retaining plate (4), or retaining plate

(5) with bearing cup replacer and a soft plastic hammer.

23. Install new encased oil seal (6) in second intermediate bearing retaining plate (3). Apply a thin even film of sealing

compound (WP 0035 00, Item 12) or (WP 0035 00, Item 13) to clean mating surface of seal. Position seal with lip

toward bore. Use a flat block of wood and mallet and tap seal in place so that top surface is .09 to .15 inch below surface

of retaining plate.

NOTE

Install bearing retaining plate with oil hole up. Most retaining plates have the word TOP

marked on metal near oil hole.

24. Determine thickness of new laminated shim (7) for bearing preload. Without shim and four new key washers (8)

installed, place output bearing retaining plate (4) on gearcase cover. Lube four cap screws (9) with engine oil. Secure

plate to cover with screws. Tighten screws (9) uniformly to 1416 lb-in (1.51.8 Nm) torque. Use torque wrench

(WP 0033 00, Item 41). Rotate gear train by hand one revolution in each direction to check freedom of movement.

Recheck installation procedures if binding is detected.

0017 00-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |