|

|||

|

|

|||

|

Page Title:

Finding the Right Troubleshooting Procedure-continued |

|

||

| ||||||||||

|

|

TM 9-2520-238-34

INTRODUCTION TO HOW TO USE TROUBLESHOOTING--Continued

0004 00

Check title to make sure you are troubleshooting the correct system for the problem. Next, read the INITIAL SETUP

carefully. Make sure you have all the items listed in the INITIAL SETUP. Some access steps in Equipment Conditions may

not need to be performed depending on the fault location. It's up to you to decide which are necessary for your particular

problem.

TM 9-2520-238-34

0010 00

DIFFERENTIAL MAKES EXCESSIVE NOISE OR VIBRATES WHILE MOVING

INITIAL SETUP:

Maintenance Level

References

Direct/General Support

See your-20

Tools and Special Tools

Equipment Condition

General mechanic's tool kit (WP 0034 00, Item 37)

Differential removed from carrier (See your -20)

Personnel Required

Disassemble for inspection per repair differential right

angle gearbox (WP 0029 00)

Track Vehicle Repairer

Repair output shaft assemblies (WP 0025 00)

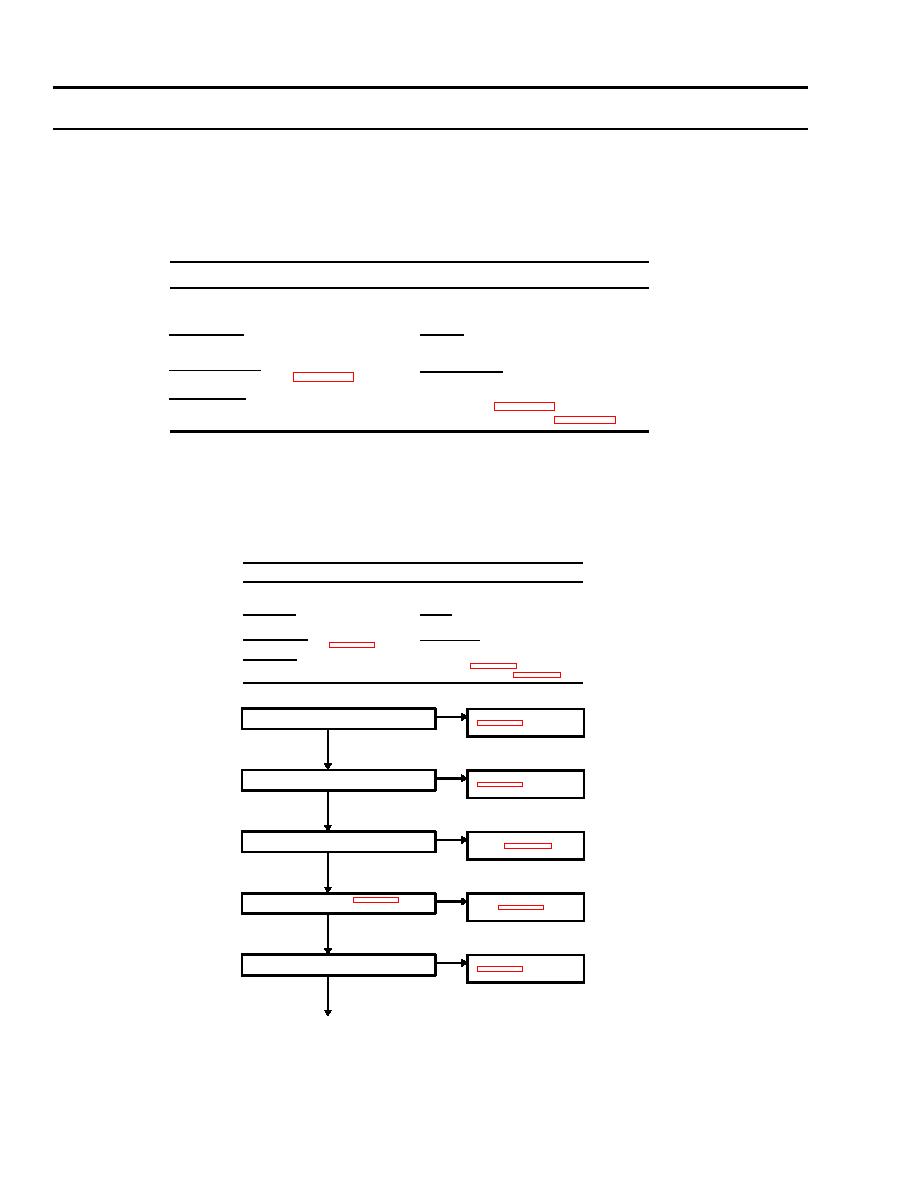

Now you're ready to begin troubleshooting. Look at the first block. Read step1. If the answer to the question, "Has bevel gear

backlash been adjusted?" is YES, follow the Yes arrow to the next box. Read step 1. If the answer to the question, "Has shaft

gear bearing been adjusted?" is YES , follow the YES arrow to the next box. Follow the same procedure or each box. If you

reach the last box on this page and the answer to the question "Are output shaft bearings serviceable?" is YES, follow YES

arrow to the next box.

TM 9-2520-238-34

0010 00

DIFFERENTIAL MAKES EXCESSIVE NOISE OR VIBRATES WHILE MOVING

INITIAL SETUP:

Maintenance Level

References

Direct/General Support

See your-20

Tools and Special Tools

Equipment Condition

General mechanic's tool kit (WP 0034 00, Item 37)

Differential removed from carrier (See your -20)

Personnel Required

Disassemble for inspection per repair differential right

angle gearbox (WP 0029 00)

Track Vehicle Repairer

Repair output shaft assemblies (WP 0025 00)

T

TN

NO

1. Inspect bevel gear backlash to see if it has been adjusted.

1. Adjust bevel gear backlash

2. Has bevel gear backlash been adjusted?

2. Verify no faults found.

YES

Y

YN

NO

1. Inspect shaft gear bearing to see if it has been adjusted.

1. Adjust shaft gear bearing

2. Has shaft gear bearing been adjusted?

2. Verify no faults found.

YES

2Y

2YN

NO

1. Inspect shaft gear bearings for damage.

1. Replace damaged shaft gear

2. Are shaft gear bearings undamaged?

bearings (WP 0029 00).

2. Verify no faults found.

YES

3Y

3YN

NO

1. Inspect bevel gear shaft bearings (WP 0029 00).

1. Replace damaged bevel gear shaft

2. Are bevel gear teeth undamaged?

bearing (WP 0029 00).

2. Verify no faults found.

YES

4Y

4YN

NO

1. Inspect output shaft bearings.

1. Replace output shaft bearings

2. Are output shaft bearings serviceable?

2. Verify no faults found.

YES

0010 00-1

0004 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |