|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-238-34

EQUIPMENT DESCRIPTION AND DATA -- Continued

0002 00

PIVOT BRAKE RELEASED. Upon release of hydraulic pressure, wave washers in the housings pull the pistons and linings

away from the brake disk and releasing the disk and output shaft on the differential.

REPAIR FINAL DRIVE ASSEMBLIES

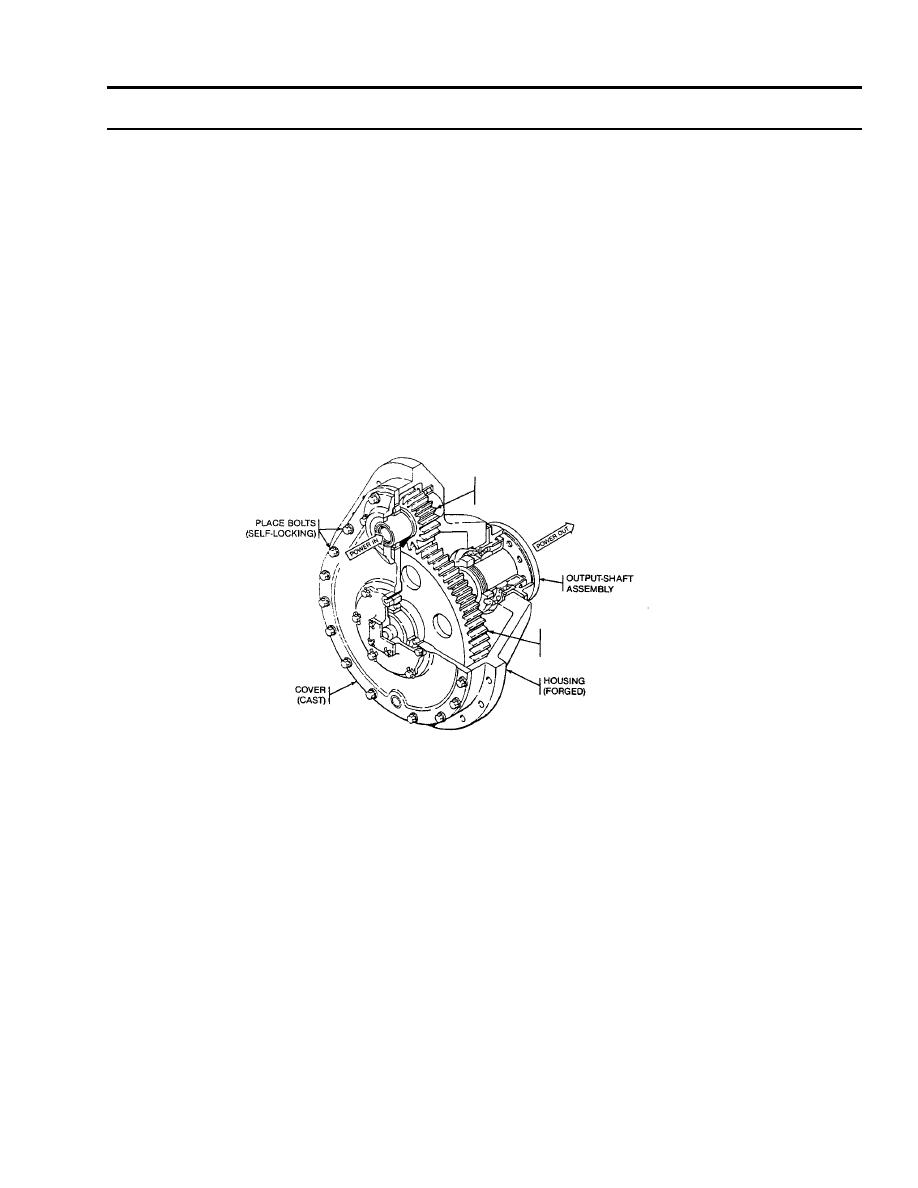

GENERAL. Final drive assemblies transmit power from the steering control differential to the track drive sprockets. The final

drives consist of reduction gears encased in a forged housing with a cast cover and use a flat gasket to seal the cover to the

housing.

FINAL DRIVE ASSEMBLIES A AND B. Final drive A has a spur gearshaft with 13 teeth and a spur gear with 56

teeth, resulting in a gear ratio of 4.308:1. Final drive B has a spur gearshaft with 14 teeth and a spur gear with 55 teeth,

resulting in a gear ratio of 3.929:1.

SPUR GEARSHIFT

SPUR GEARSHAFT

((14TEETH ON ASSEMBLY )B)

14 TEETH ON ASSEMBLY

(13 TEETH ON ASSEMBLY A) )

((13 TEETH ON ASSEMBLY A)

SPUR GEAR

(55 TEETH ON ASSEMBLY B)

(56 TEETH ON ASSEMBLY A)

Final Drive Assembly A and B

0002 00-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |