|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 750-245-4

interface, or if proper heat balance has not been

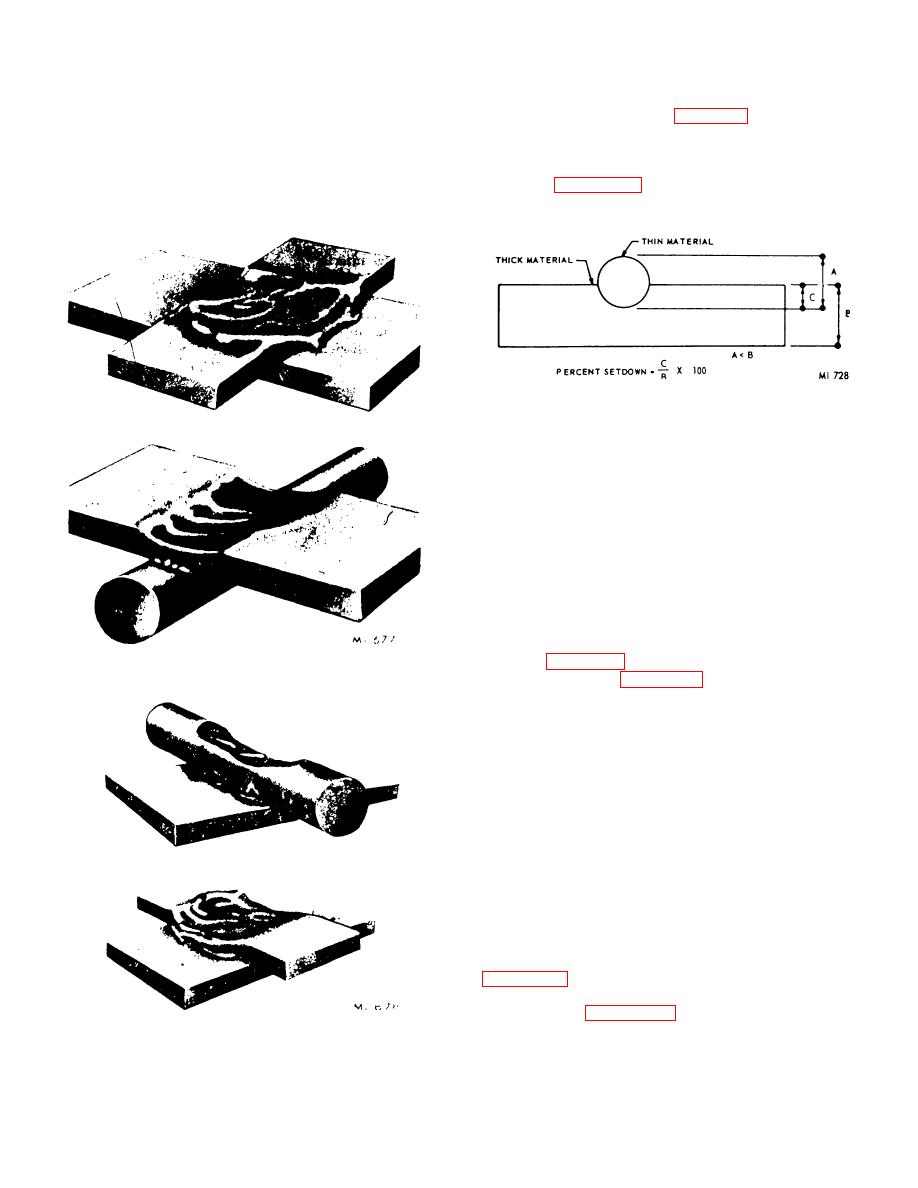

8-23. Excessive Setdown (Fig. 8-10)

attained, the contact area will melt. In certain cases, a

Setdown is the degree to which the thinner of the

small amount of surface fusion cannot be avoided.

materials being joined is physically forced into the

However, it is desirable to keep this to a minimum,

thicker material. It is expressed in percent, and is

preferably below 10 percent of the lead diameter.

shown in figure 8-10. Setdown should not exceed 50

percent.

Figure 8-10. Setdown.

8-24. Insufficient Weld

An insufficient weld is one in which fusion or forging

action has occurred, but not to the extent that minimum

weld strength requirements can be met. It is extremely

difficult to detect, and if this condition is suspected to

exist, a number of samples should be obtained from the

machine which produced the questionable welds and

pull tests made. In certain cases, as in round materials

welded to rectangular materials, it may be possible to

detect insufficient welds by observing the fillet at the

interface. The fillet should be evident at least along 75

percent of the interface. Normally, a defective weld will

exhibit two or more of the above conditions. For

example, figure 8-3 is an offset weld in which a weld

Figure 8-8. Pitted weld.

splatter is evident. Figure 8-5 exhibits cracks, excess

surface fusion, and excess metal bulging.

8-25. Destructive Inspection

a. Destructive inspection is made by either a pull-

test or metallurgical test. Pull-testing is time consuming

and expensive, and it destroys the product.

Nevertheless, it is the only method available at the

present time for obtaining quantitative data about the

parameters of a weld. Since this method is destructive,

it must be used only on a sampling basis.

b. The pull-test is commonly referred to as a

tensile test of the weld. The test consists basically of

pulling the weld apart by applying a tensile force of

opposite direction to each lead. Besides the tensile

force, there is also a shear force, and, in some

instances, a torsional force applied at the weld joint.

use by various companies for pull-testing welds.

Method A of figure 8-11 is the preferred pull-test

method. This method applies an additional stress to the

Figure 8-9. Excessive surface fusions.

joint.

8-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |