|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 750-245-4

3-12. Wiring Harness Assemblies

Wiring harness assemblies are normally used internally

in chassis assemblies. They do not require weather

proofing protection and only in some cases require

potting of plug and jack assemblies. The inspector

should inspect for proper stripping, splices, lacing, wire

color, and proper wire size of replaced wiring.

a. Stripping.

Proper stripping is important to

accomplish a good solid and electrical connection. If

stripping is not properly done, arcing and burning may

result. The inspector will have to perform an in-process

inspection to insure that proper stripping is being

accomplished.

(1) Stripping is usually accomplished by a

mechanical stripping tool or a thermal stripper.

Generally, nonadjustable type mechanical strippers are

used because of the nonavailability of thermal-type

strippers. These mechanical strippers should never be

used on wire sizes 22 or smaller if there is a tendency to

stretch the wire. Also, care should be taken to prevent

nicking or cutting of the wire strands. Nicked or cut wire

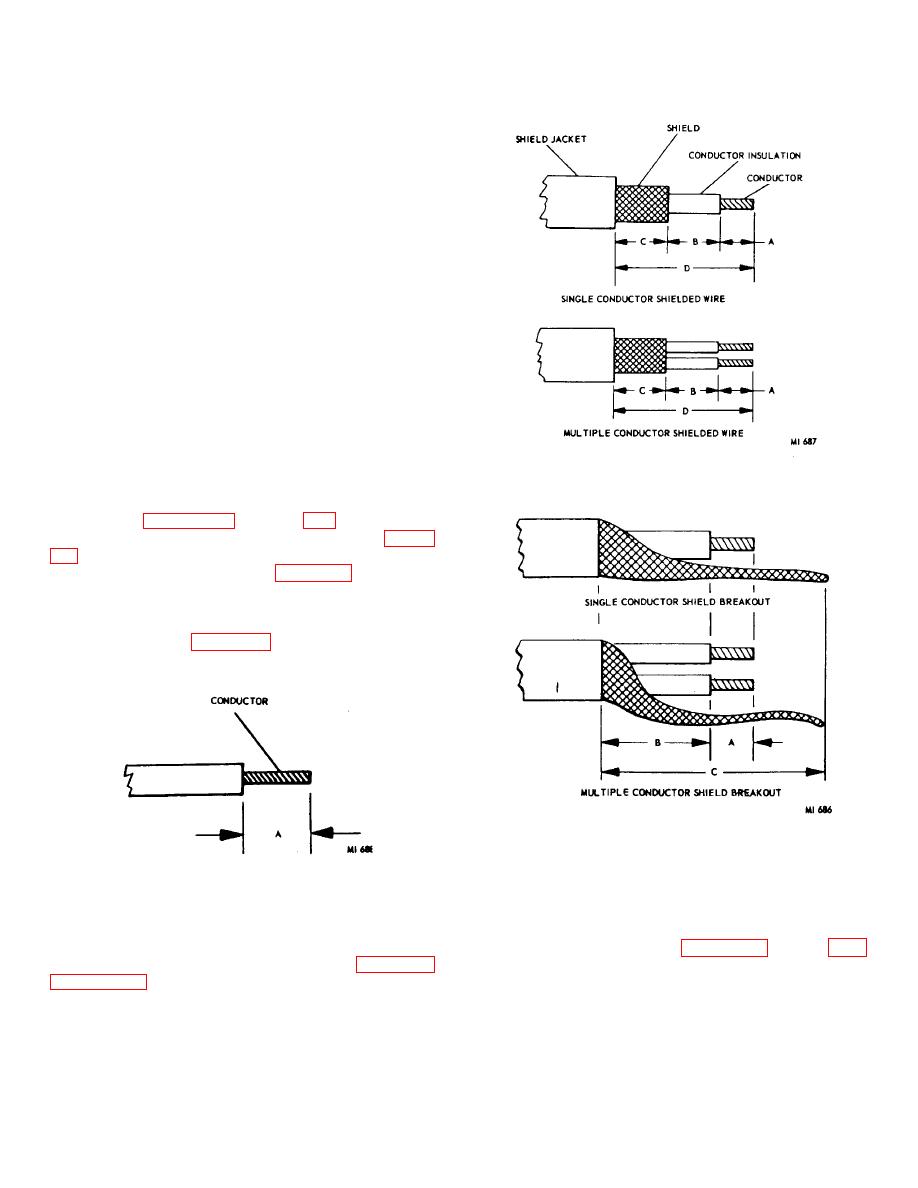

Figure 3-2. Stripping shielded conductor.

strands requires replacement of the wire if enough

length for restripping is not available.

(2) Figures 3-1 through 3-3 show proper

stripping, depending on the termination method. Figure

to the conductor plus 1/ 16 inch. Figure 3-2 illustrates a

ferrule or dead-end shield termination. Dimension C is

the length of the bowel to be crimped plus 1/16 inch.

For dead-ending, keep shield braid flush, within 1/8 inch

of the shield jacket. Figure 3-3 shows the pigtailing of

shields for grounding. Dimension C is determined by

the application.

Figure 3-3. Single and multiple conductor shield

breakout

Figure 3-1. Stripping single conductor.

c. Crimping. All crimping should be accomplished

b. Splicing.

The splicing of wiring harness

with properly qualified and calibrated tools.

The

assemblies is not recommended and should only be

inspector should inspect in-process to insure that the

accomplished as specified in the system documentation.

proper tools are being used. Figures 3-9 through 3-16

If splicing is to be accomplished tile following figures 3-4

are included to assist the inspector in determining that

the crimping is properly done.

determining that the splice is properly done.

d. Lacing. To prevent damage to insulation and

breaking of conductors caused by vibration and other

movements, the wires must be tied, together in

3-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |