|

|||

|

|

|||

|

Page Title:

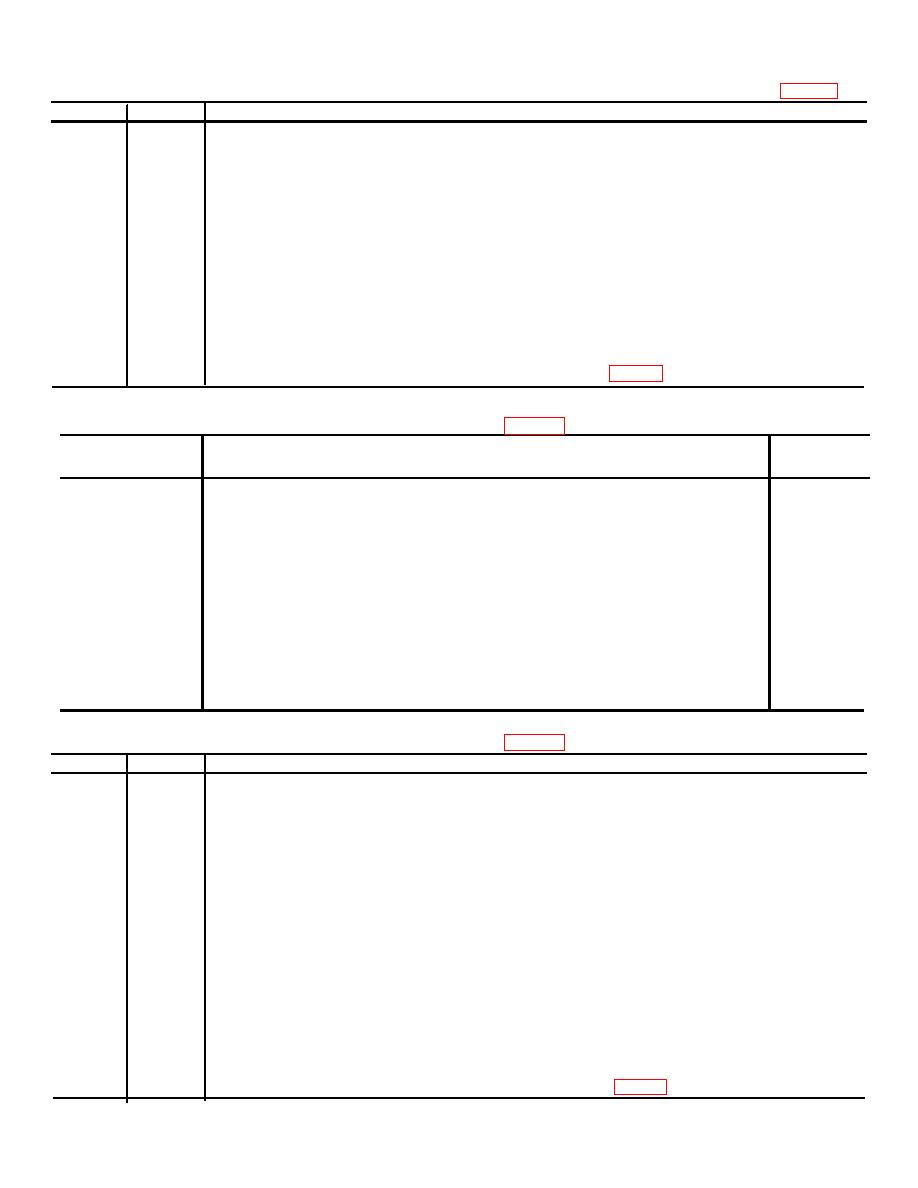

Table 6-4. Application of Material for Blocking and Tiedown of Shelters in Hold of General-Cargo Vessel (Fig 6-6). |

|

||

| ||||||||||

|

|

TM 55-5811-900-14

Table 6-4. Application of Material for Blocking and Tiedown of Shelters in Hold of General-Cargo Vessel (Fig 6-6).

Item

No. Reqd.

Application

A

2

Side braces. Each to consist of 3 x 4x 126-inch lumber. Locate against sides of shelter.

B

2

End braces. Each to consist of 3 x 4 x 102-inch lumber. Locate against front and rear of

shelter. Toenail to item A with 20d nails.

C

4

Side blocks. Each to consist of 3 x 4 x 6-inch lumber. Locate against side brace. Toenail to

item A with 20d nails.

D

2

Front blocks. Each to consist of 3 x 4 x 45-inch lumber. Locate against front end brace.

Toenail to item B with 20d nails.

E

2

Rear blocks. Each to consist of 3 x 4 x 24-inch lumber. Locate against rear end brace.

Toenail to item B with 20d nails.

F

4

Wire rope, -inch. Each to consist of a 27-foot loop, with a 2-foot overlap between ends.

Place the loop through the shackle and pad eye on the deck of vessel.

G

4

Shackles. One of each upper tiedown of shelter.

H

16

Clamps. Place four over each cable loop, overlap area, and space 3 inches apart, with a

minimum of 6 inches from ends of cable.

I

4

Pad eyes. Four are required on the floor or vessel (inset, fig 6-3).

Table 6-5. Bill of Materials for Blocking and Tiedown of Trailer Support Unit in Hold of

General-Cargo Vessel (Fig 6-8).

Item

Description

Approximate

Quantity

Lumber.......................Douglas-fir or comparable, straight-grain, free from material defects;

Fed Spec MM-L-751:

2-4-in......................................................................................................................

18 lin ft.

4- X 4-in .................................................................................................................

102 lin ft.

Nails ...........................Common, steel, flathead; bright or cement-coated; type II, style 10,

Fed Spec FF-N-105:

12d ........................................................................................................................

22.

20d ........................................................................................................................

52.

Wire rope ..................6 X 19 IWRC, improved plow steel, preformed, regular-lay; table X,

50 ft.

Fed Spec RR-W-410: 5/8 -in.

Clamps ......................Wire rope, U-bolt clips, saddled, single-grip, forged steel, Crosby heavy-duty, or equal;

24.

Fed Spec FF-C-450: 5/8 -in.

Table 6-6. Application of Materials for Blocking and Tiedown of Trailer Support Unit in Hold of

General-Cargo Vessel (Fig 6-8).

Item

No. Reqd.

Application

A

1

Lunette support. Consists of fourteen pieces of 2 x 4 x 15-inch lumber. Nail in a stack with

12d nails and place under the lunette.

B

2

Side blocks. Each to consist of one piece of 4 x 4 x 252-inch lumber. Place tightly against the

wheels on each side of the trailer.

C

2

Wheel blocks. Each to consist of one piece of 4 x 4 x 101-inch lumber. Place one piece

tightly before the front wheels and the other tightly behind the rear wheels. Toenail to item

B with 20d nails.

D

4

Braces. Each to consist of one piece of 4 x 4 x 6-inch lumber. Place against item C and nail

into item B with 20d nails.

E

2

Spreader blocks. Each to consist of one piece of 4 x 4 x length-to-suit (about 42 in.). Place in

between items A and B. Nail if needed.

F

6

Side brace. Each to consist of one piece of 4 x 4 x length-to-suit lumber (about 6 in.). Place

between cargo loads. Nail if needed.

G

4

Wire rope, each about 5/8 inch x 12.5 feet. Form a complete loop, with cable placed between

the tiedown shackle and pad eye.

H

24

Clamps. Place on each cable loop at the overlap area; space 3- inches apart, minimum of 6

inches from the end of cable.

I

4

Pad eyes. Four are required on the floor of vessel (insert, fig 6-3).

6-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |