|

|||

|

|

|||

|

Page Title:

Loading the MW24C Scoop Loader on Special Purpose Flatcars |

|

||

| ||||||||||

|

|

TM 55-3805-262-14

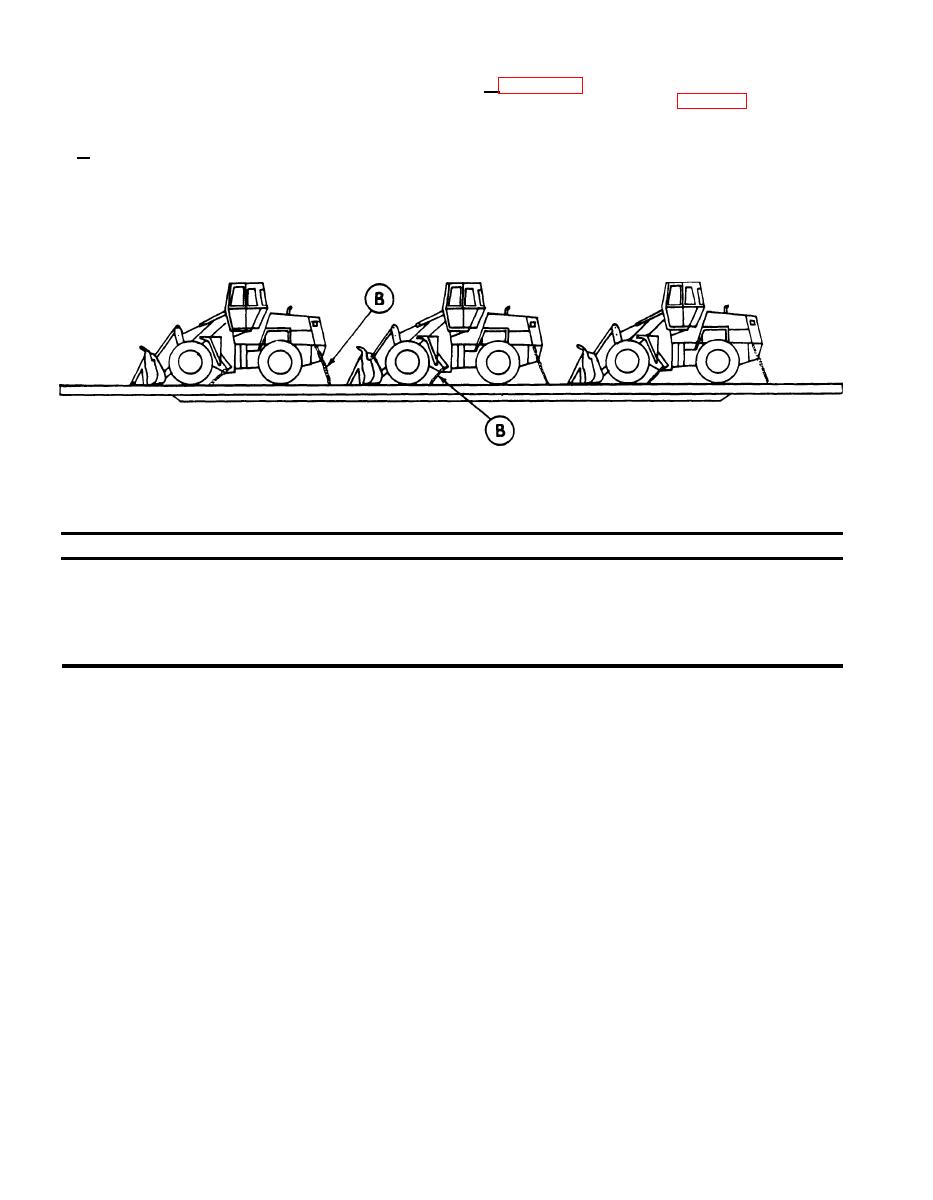

b. Figure 7-4 shows the scoop loader on a center

7-5. Loading the MW24C Scoop Loader on

tiedown rail-equipped flatcar. Table 7-3 presents the

application of chain tiedowns for securing the vehicle

Special Purpose Flatcars

on a center tiedown flatcar.

a. The scoop loader maybe placed in the tiedown

position on the flatcar by a crane, or it may be

driven or towed onto the flatcar provided a suitable

ramp or bridge is available.

Figure 7-4. Tiedown of MW24C scoop on flatcars with center tiedown rails.

Table 7-2. Application of Materials for Blocking and Tiedown of MW24C loader on CONUS General-Purpose Flatcar

Application

No. Required

Item

Brakewheel clearance. Minimum clearance required is 6 inches above, in back of, and on both sides of

A

and 4 inches underneath wheel.

4 ea unit

l/2-inch diameter alloy steel chain proof-tested to minimum of 22,500 pounds for vehicles weighing

B

from 16,000 to 25,000 pounds inclusive.

l/2-inch diameter alloy steel chain, extra strength, proof-tested to minimum of 27,500 pounds for

vehicles weighing from 25,000 to 40,000 pounds inclusive.

GENERAL INSTRUCTIONS

1. When ordering specialized railway equipment, shippers should specify cars equipped with tiedown devices in the quantity shown in

item B. When carriers furnish cars that do not have built-in chains and tensioning devices, chains and turnbuckles of appropriate size

and strength will be used to secure vehicles. Load binders are not to be used in place of turnbuckles to tension tiedown chains.

2. Vehicles must be faced in the same direction and uniformly spaced along the length of the car to allow sufficient space at each end of

the car and between the vehicles for securement. Tiedowns should be applied parallel to each other at the same end of the vehicle and

from the vehicle tiedown point to the car tiedown facility. The angle of the tiedown should be as close as possible to 45. When the

length of vehicles loaded on an 89-foot car precludes facing all cars in the same direction, one vehicle may be reversed to ensure

application of tiedown at a floor angle of 45.

3. Air tanks must be drained.

4. Gearshift levers on vehicles equipped with automatic or standard transmissions must be wire-tied in neutral position.

5. Open hooks must be secured with wire over the opening to prevent the hook from being disengaged from chain link to which it is

secured.

6. Turnbuckles used to tighten chains must be wired or locked to prevent them from turning during transit unless turnbuckles are

equipped with self-locking devices.

7. When vehicles are shipped in a loaded configuration, the gross weight of the vehicle and cargo combined must be determined to

assure that the proper size and/or number of tiedowns are used to secure the vehicles to the railcar.

7-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |