|

|||

|

|

|||

|

Page Title:

Quality Assurance Requirements (10 CFR 71.101 and 71.137) |

|

||

| ||||||||||

|

|

TM 55-315

as appropriate, to determine compliance with the requirement.

(8) If the maximum normal operating pressure of a package is likely to exceed 0.35 kilogram per square

centimeter (gauge), the internal pressure of the container will not exceed the design pressure.

(9) External radiation and contamination levels are within the allowable limits.

n. No person may offer for transport a package of radioactive materials until the temperature of the packaging

system has reached equilibrium (see also e above) unless, for the specific contents, he has ascertained that the

maximum applicable surface temperature limits cannot be exceeded.

o. No person may offer for transport aboard a passenger-carrying aircraft any radioactive material unless that

material is intended for use in, or incident to, research or medical diagnosis or treatment, or is excepted under the

provisions of 49 CFR 175.10.

4-5. Quality Assurance Requirements (10 CFR 71.101 and 71.137)

Each activity engaged in design, fabrication, assembly, testing, maintenance, or use of packaging shall establish an

approved quality assurance program to be applied to the activity's function(s). Quality assurance program requirements

are further explained in chapter 9.

4-6. Requirements for Specification Containers (49 CFR 173.24)

a. Each specification container must be marked as follows:

(1) In an unobstructed area with letters and numerals identifying the container specification; for example,

DOT-1A, DOT-17E-304HT, or DOT-23G40 (see 49 CFR 178.0-2).

(2) With the name and address or symbol of the person making the mark specified in (1) above. Symbol

letters, if used, must be registered with the Bureau of Explosives. Duplicate symbols are not authorized.

(3) With stamped, embossed, burned, printed, or other markings to provide adequate accessibility,

permanency, and contract so as to be readily apparent and understood.

(4) With at least 1/2-inch-high letters and numeral, unless otherwise specified.

b. Packaging that does not comply with the applicable specifications listed in 49 CFR 178 and 179 must not be

marked to show such compliance (see 49 CFR 178.0-2 and 179.1).

c. For specification containers, compliance with the applicable specifications in 49 CFR 178 and 179 shall be

required in all details, except as otherwise provided in this paragraph.

4-7. Materials Used in Packaging (49 CFR 173.24)

a. Steel used shall be low-carbon, commercial quality. Stainless, open hearth, electric, basic oxygen, or other

similar quality steels are acceptable. Steel sheets of specified gauges shall comply with table 4-1.

b. Lumber used shall be well seasoned, commercially dry, and free from decay, loose knots, knots that would

interfere with nailing, and other defects that would materially lessen the strength.

c. Welding and brazing shall be performed in a workmanlike manner using suitable and appropriate techniques,

materials, and equipment.

d. Packaging materials and contents shall be such that no significant chemical or galvanic reaction will occur

among any of the materials in the package.

e. Closures shall be adequate to prevent inadvertent leakage of the contents under normal transport conditions.

Gasketed closures shall be fitted with gaskets of efficient material that will not be deteriorated by the contents of the

container.

f. Nails, staples, and other metallic devices shall not protrude into the outer packaging in such a manner as to be

likely to cause failures.

g. The nature and thickness of the packaging shall be such that, during transport, friction will not generate any

heat likely to decrease the chemical stability of the contents.

h. The polyethylene used must be of a type compatible with the lading and must not be permeable to an extent

that a hazardous condition could be caused during transport and handling.

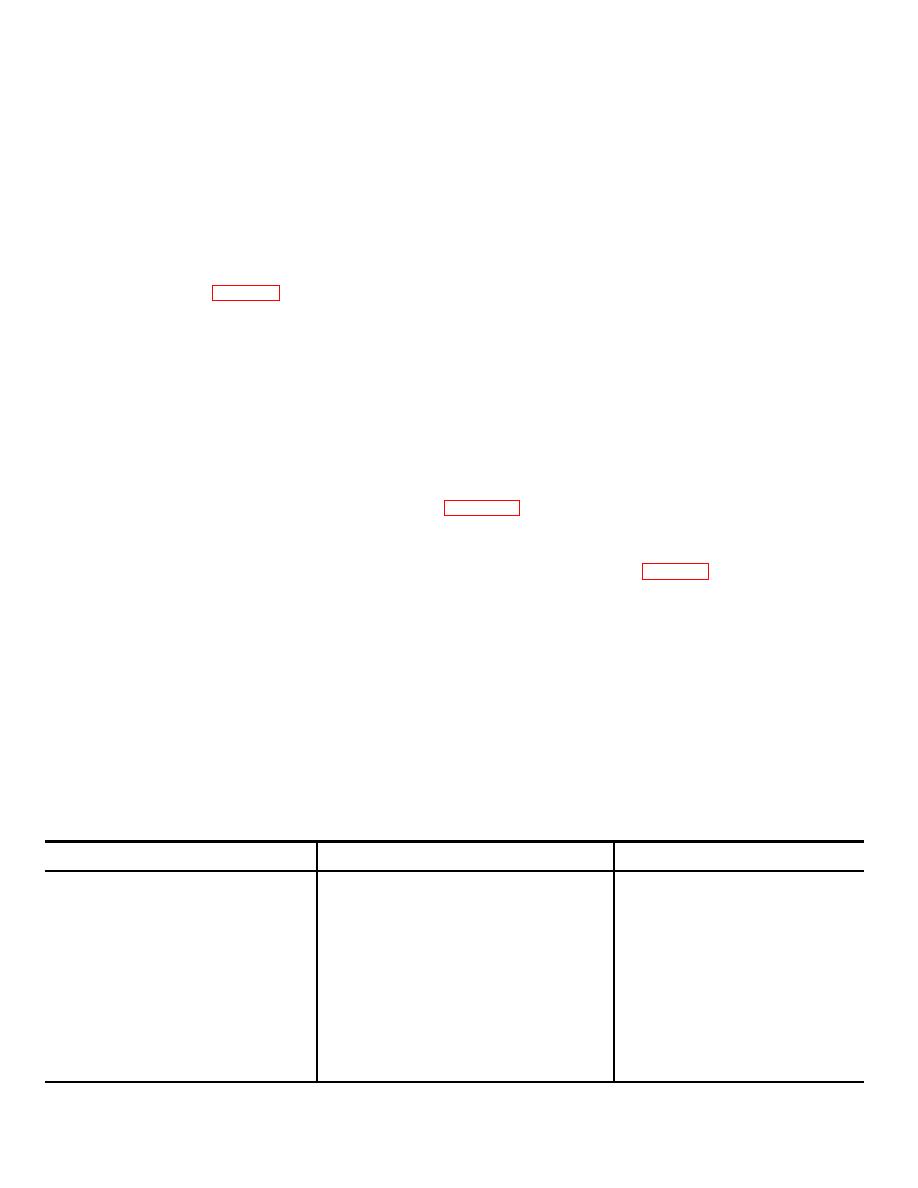

Table 4-1. Sheet Steel Dimensions

Nominal thickness

Minimum thickness

Gauge No.

(in.)

(in.)

12

0.1046

0.0946

13

0.0897

0.0817

14

0.0747

0.0677

15

0.0673

0.0603

16

0.0598

0.0533

17

0.0538

0.0478

18

0.0478

0.0428

19

0.0418

0.0378

20

0.0359

0.0324

22

0.0299

0.0269

23

0.0269

0.0239

24

0.0239

0.0209

26

0.0179

0.0159

28

0.0149

0.0129

30

0.0120

0.0110

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |