|

|||

|

|

|||

|

Page Title:

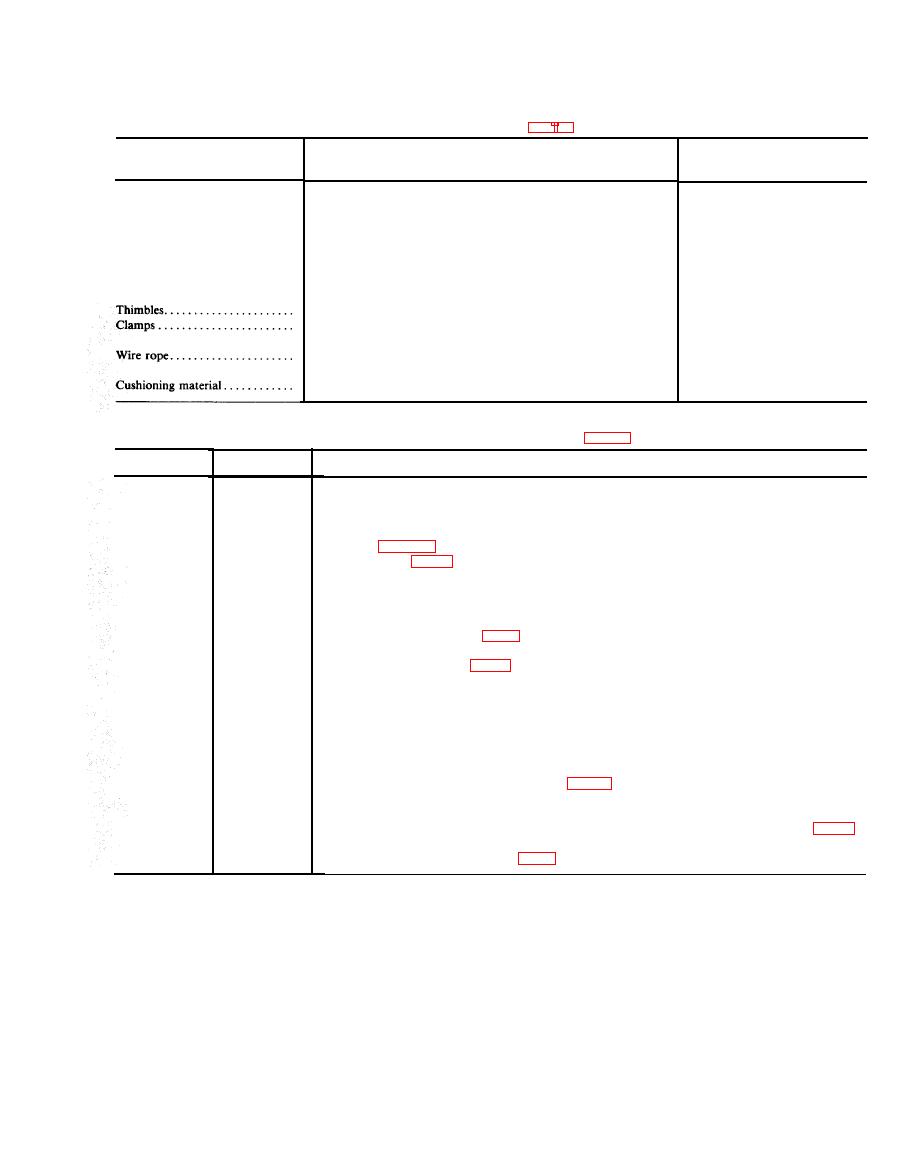

Table 7-1. Bill of Materials for Blocking and Tiedo wn of Truck Tractor, M746 and M911, on CONUS General-Purpose Flatcar (Fig... |

|

||

| ||||||||||

|

|

TM 55-2320-258-14

Approximate

Item

Description

quantity

Lumber . . . . . . . . . . . . . . . . . . . . . . .

Douglas-fir or comparable, straight-grain, free from material de-

fects; Fed Spec MM-L-751H: 2- x 4-in. . . . . . . . . . . . . . . . . . . . .

108 linear ft

2- x 6-in. . . . . . . . . . . . . . . . . . . . .

77 linear ft

12 linear ft

6- x 8-in. . . . . . . . . . . . . . . . . . . . .

Nails . . . . . . . . . . . . . . . . . . . . . . . . .

Common, steel; flathead, bright or cement-coated; Fed Spec

FF-N-105B:

12d . . . . . . . . . . . . . . . . . . . . . . . . . . .

60

AM.. . . . . . . . . . . . . . . . . . . . . . . . . .

224

God . . . . . . . . . . . . . . . . . . . . . . . . . . .

56

Standard, open-type 5/8-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

Wire rope, U-bolt clips, saddled, single-grip, steel, Crosby heavy-

duty, or equal; Fed Spec FF-C-450D: 5/8-in . . . . . . . . . . . . . . . . . . .

48

6 x 19, IWRC; improved plow steel; preformed, regular-lay; table

X, Fed Spec RR-W-410C:5/8-in. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

120 ft

Waterproof paper, burlap, or other suitable material . . . . . . . . . . . .

as required

Tractor, M746, on CONUS General-Purpose Flatcar (Figs 7-1 and 7-3)

Item

No. required

Application

A

Brake wheel clearance. Minimum clearance required in 6 in. above, in back of, and on both sides of,

and 4 in. underneath wheel, 12-inch minimum clearance from end of car to load, extending from

center of brake wheel to side of car and 6 ft above car floor (fig 7-l).

B

Blocks. Each to consist of one piece of 2- x 6- x 25-in. lumber. Locate one block against wheels as

8

shown in figure 7-1, and nail to car floor with five 20d nails.

c

8

detail 1. Locate one block on top of each item B with 45-degree side against tire. Nail heel of block

to item B with three 40d nails. Toenail sides of block to car floor through item B with two 40d nails

on each side. (Pattern 16)

1 ea item E

Cushioning material. Locate bottom portion under item E, and between tire anditem E seas to extend

D

2in. above item E (detai12, fig 7-3).

4

E

Side block. Each to consist of one piece of 2- x 6- x 108-in. lumber and three pieces of 2- x 4- x

108-in. lumber (detai12, fig. 7-3). Nai12- x 6- x 108-in. piece to edge ofbottom2- x 4- x 108-in.

piece with fifteen 12d nails. Place against inside of tires and cushioning material and nail to car floor

through 2- x 4- x 108-in. piece with twelve 20d nails. Nail other two 2- x 4- x 108-in. pieces to

one below in the same manner. (Pattern 89)

Brace. Each to consist of one piece of 2- x 6- x length to-suit (approximately 72 in.) lumber. Locate

F

4

one under each axle between items E Nail to car floor with ten 20d nails.

Wire rope. Each to consist of one piece 5/8-in. 6x19, IWRC wire rope, length as required

G

8

(approximately 20 ft). Form a complete loop between tiedown shackle and appropriate stake pocket

at a maximum angle of 45 degrees (detail 3. fig. 7-3). Wire rope ends should overlay approximately

24 in.

H

16

Thimbles. Place one under wire rope at each place where rope passes over bottom edge of stake pocket

Clamps. Place four on each item H at overlap area. Space clamps 31/2 in. apart with a minimum of 6

48

J

in. from endsof wire rope (detail 3, fig 7-3). Place one on each item J as indicated above.

GENERAL INSTRUCTIONS

1. Set handbrakes, and block and wire levers in place.

2. Place and wire-tie gearshift levers in the neutral position.

3. See General Rules 1, 2, 3, 4, 5, 14, 15, 19A, and 19B, Section I of the Rules Governing the Loading of Commodities on Open-Top Cars

and Trailers published by the Association of American Railroads for further details.

4. Tension wire rope with inapplicable sized come-along mechanical hoist or equal tensioning device.

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |