|

|||

|

|

|||

|

Page Title:

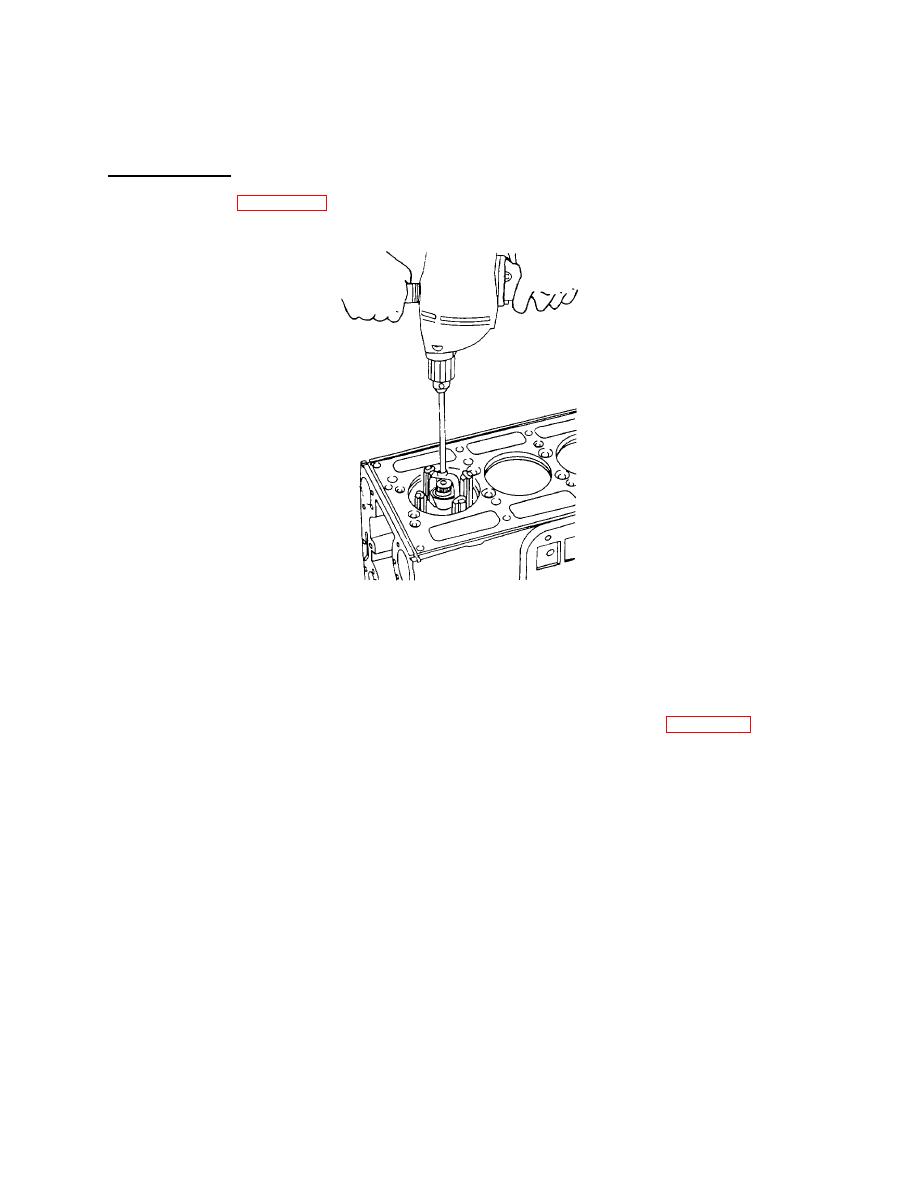

Figure 4-53. Honing Bore of Cylinder Block. |

|

||

| ||||||||||

|

|

TM 55-1930-208-24

4-16. BLOCK, CYLINDER-Continued.

c. Repair-Continued.

(2)

Insert hone (figure 4-53) in bore and adjust stones snugly to the narrowest section. When correctly

adjusted, the hone will not shake in the bore, but will drag freely up and down when the hone is not

running. Use 120 grit stones J5902-14.

Figure 4-53. Honing Bore of Cylinder Block.

(3) Remove hone when bore is fairly clean. Measure bore. Determine which spots must be honed most.

Where and how much to hone can be judged by feel.

(4) Wash cylinder block thoroughly after honing operation is completed.

(5) Measure the entire bore of each cylinder with cylinder bore gage J5347-01 (figure 4-54) which has a dial

indicator calibrated in .0001 inch increments. The standard block bore is 4.6260 inch to 4.6275 inch.

Place the bore gage in the master ring gage J8386-01 which has an I.D. of 4.6270 inch and set the dial to

zero. Take measurements on the cleaned-up surface only at positions A, B, C, D, E, and F in the bore on

axis 450 apart. Read the measurements from the zero mark on the gage.

4-72

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |