|

|||

|

|

|||

|

Page Title:

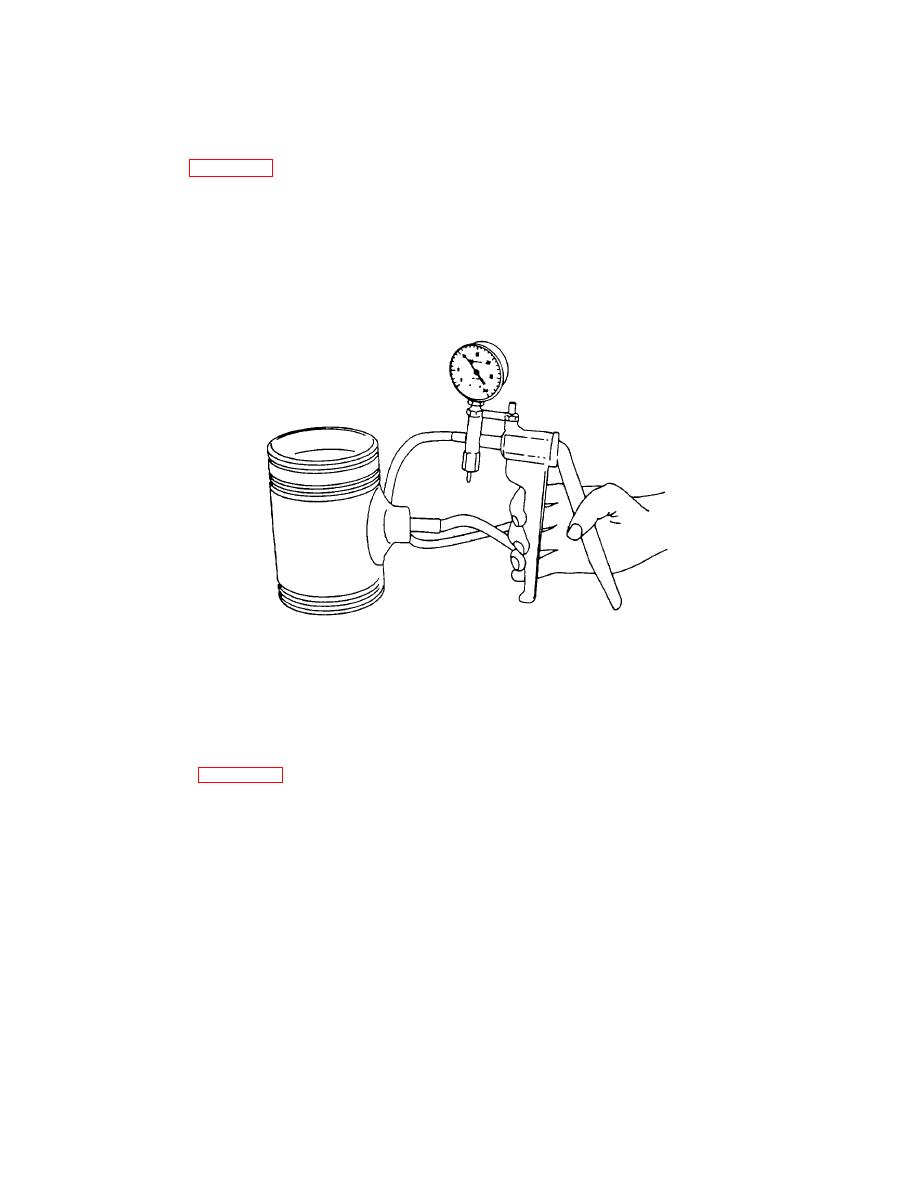

Figure 4-30. Checking Piston Pin Retainer for Proper Sealing Using Tool J23987-01 |

|

||

| ||||||||||

|

|

TM 55-1930-208-24

4-11. PISTONS AND CONNECTING RODS - Continued.

f. Reassembly - Continued.

(9) Refer to figure 4-30 and check each retainer for proper seating with leak detector J23987-01. Place the

suction cup over the retainer and hand operate the lever to pull a vacuum of ten inches on the gage.

(10) Measure piston skirt diameter lengthwise and crosswise of piston pin bore. Measurements should be taken

at room temperature (70 or 21 ).

F

C

(11) The piston-to-liner clearance, with new parts, will vary with the particular piston and cylinder liner. A

maximum clearance of .012 inch is allowable with used parts.

Figure 4-30 .

Checking Piston Pin Retainer for Proper Sealing Using Tool J23987-01 .

(12) With cylinder liner installed in cylinder block, hold piston skirt upside down in the liner and check clearance

in four places 90apart.

(13) Refer to figure 4-31 and use feeler gage set J5438-01 to check the clearance. The spring scale attached to

the proper feeler gage, is used to measure the force in pounds required to withdraw feeler gage.

4-38

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |