|

|||

|

|

|||

|

Page Title:

Table 2-1. Preventive Maintenance Checks and Services (PMCS) |

|

||

| ||||||||||

|

|

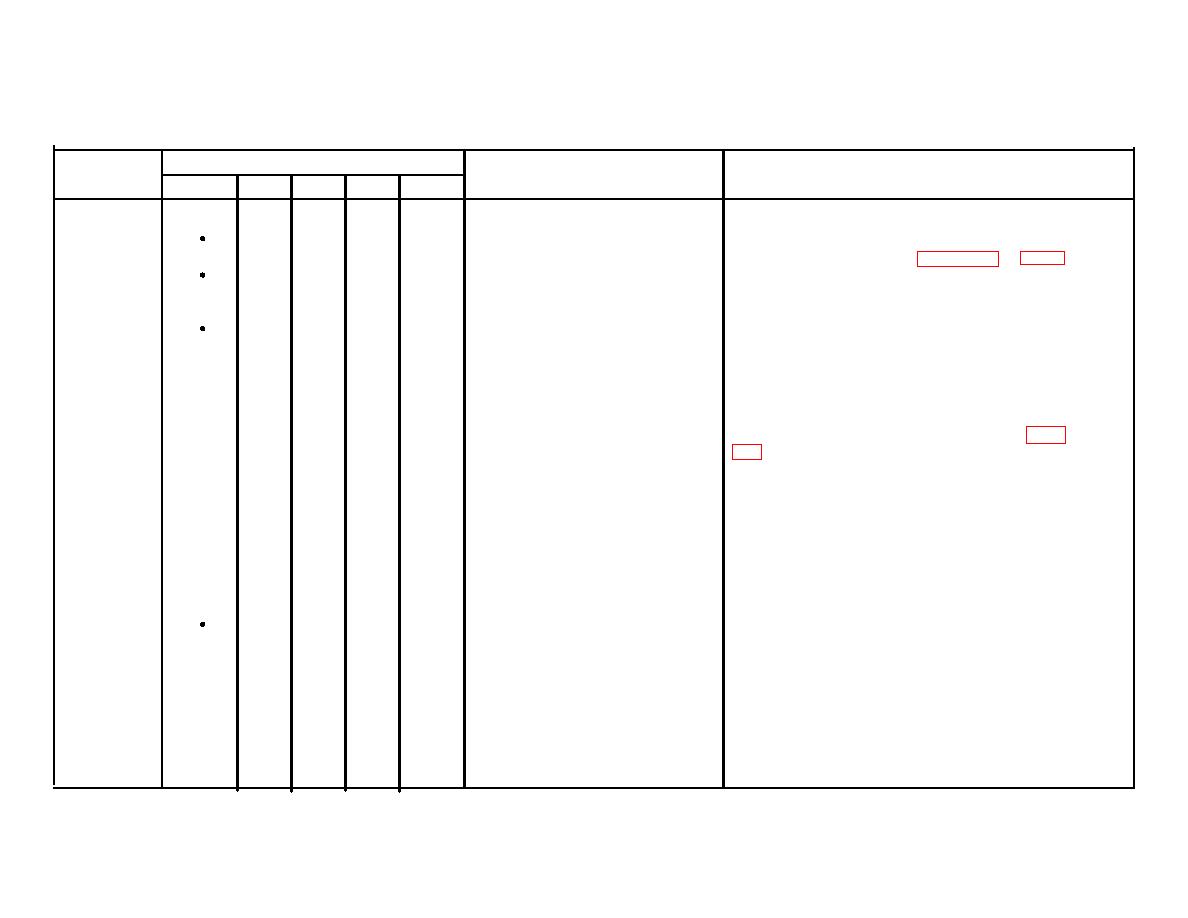

TM 55-1905-223-24-17

Table 2-1. Preventive Maintenance Checks and Services (PMCS)

D - Daily

M - Monthly

B - Bimonthl y S - Semiannually

A - Annually

Item

Intervals

Items To Be

No.

D

M

B

S

A

Inspected/Serviced

Procedures

Filters in airflow

Visually check for buildup of dirt and debris.

1

sources (A/C-1, 2. and 3)

Replace filter as necessary (paras. 2-32 or 2-33).

2

All air flow intakes and

Make sure that all air flow intakes and outlets are

outlets

clear of blockage or obstruction. Move

obstructions as required for free air flow.

3

Operating pressures on

Visually check the high (discharge) and low

A/C-2; accommodations

(suction) pressures on the fixed manifold gauges

(compressor running)

located on the lower portion of

the unit. The high

pressure should be between 170 and 230 psig. The

low pressure should be between 58 and 72 psig. If

pressures are not within this range, refer to Table

2-2, Troubleshooting.

NOTE

There are no fixed manifold gauges

for observing operating pressures

on A/C-1 and 3 (self-contained units).

Pressures are checked on these units

with portable gauge manifold as a

troubleshooting function only.

4

All unit and convection

Visually check for buildup of dirt or debris on

heaters

exterior of heater surfaces.

WARNING

Turn electrical power off.

Turn electrical power to the heater off and clean

with rags, soft brush, or vacuum cleaner.

2-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |