|

|||

|

|

|||

|

Page Title:

LUBRICATION AND ADJUSTMENT OF WHEEL BEARINGS. |

|

||

| ||||||||||

|

|

TM 55-1730-224-13 & P

LUBRICATION AND ADJUSTMENT OF WHEEL BEARINGS.

1. Remove wheel, hub cap, cotter pin and slotted nut.

2. Remove hub. Inspect grease seal for defects. Inspect brake

linings for signs of grease.

3. Repack bearings using automotive and artillery grease. Military

Specification MIL-G-10924.

4. Replace hub. Secure with slotted nut.

5. Place wheel on hub. Secure with lug nuts.

6. Rotate wheel and tighten slotted nut until slight drag is felt.

Back off slotted nut about 1/8 turn to nearest cotter pin slot.

7. Install cotter pin and hub cap.

8. Tighten lug nuts.

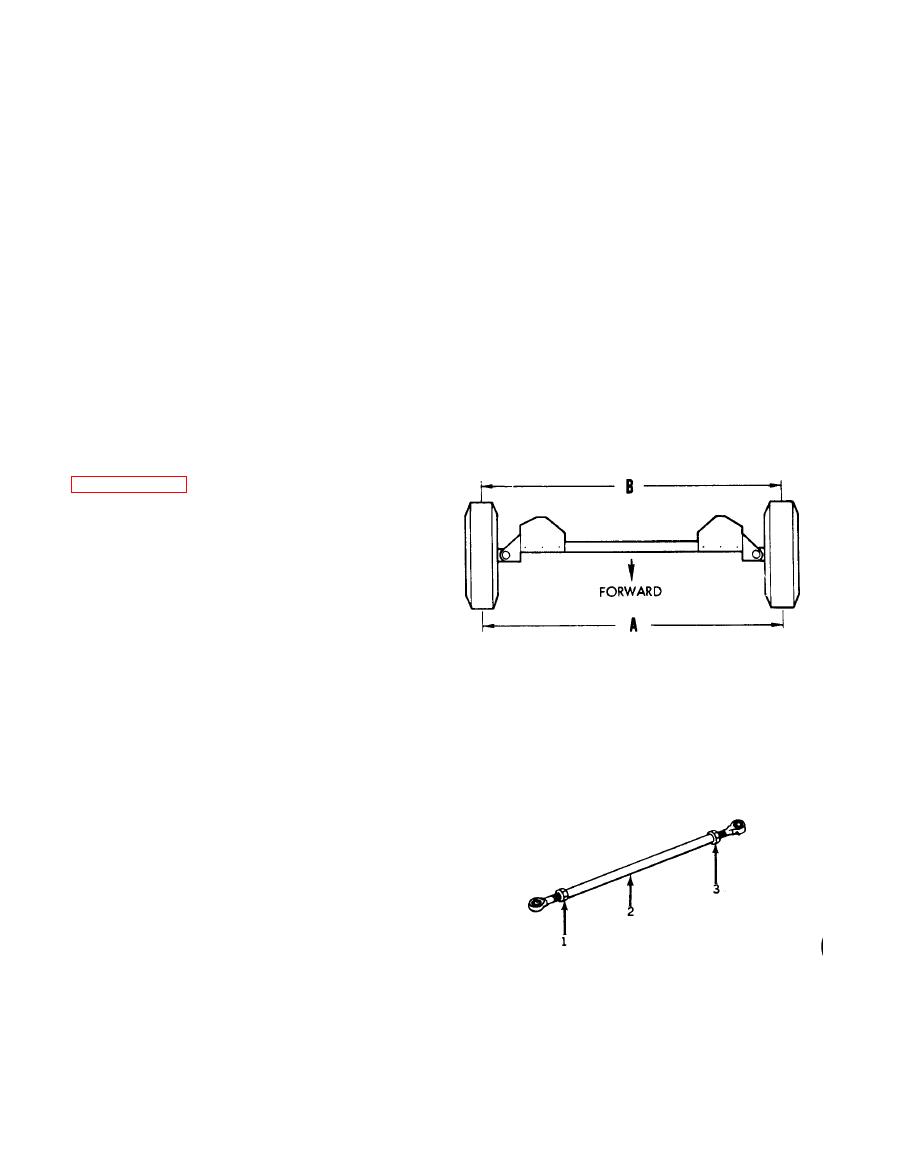

a. Checking.

1. Adjust wheel bearings. See

floor or area.

2. Position tow bar straight

ahead.

3. Measure between tread

centers at hub height behind

tires. (Measurement B)

4. Measure between tread

centers at hub height in front of

tires. (Measurement A)

5. Measurement A must be 1/16

inch less than measurement B.

b. Adjusting. If measurement A

is too short, lengthen tie rods.

If measurement A is too long,

shorten tie rods.

1. Loosen 2 locknuts (1) and (3)

on both tie rods.

2. Turn tubes (2) to shorten

or lengthen tie rods as needed.

3. Check adjustment.

4. When measurements are

correct, tighten locknuts.

3-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |